Nonwoven Polyester and Glass Core Reinforcement

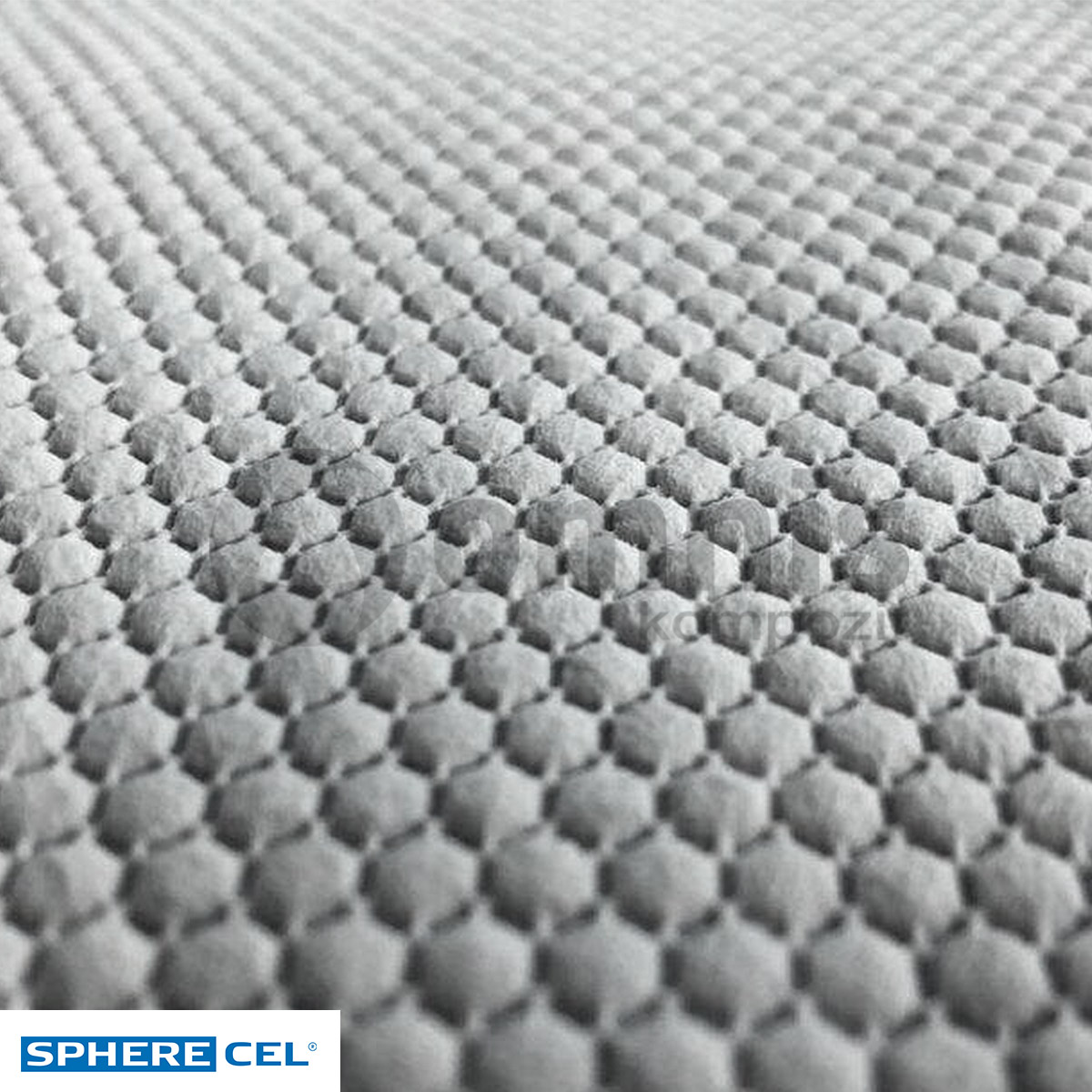

Non-woven polyester is a form of polyester fabric made by bonding and entangling polyester fibers together without the use of traditional weaving or knitting processes. This innovative material is characterized by its uniform structure, flexibility, and strength. It is widely appreciated for its versatility and efficiency in various applications, including composite material reinforcement. Its unique fabrication process results in a fabric that offers exceptional durability, dimensional stability, and resistance to chemicals and physical stress, making it an ideal choice for industries looking to enhance the performance and longevity of their products.

How is non-woven polyester used in composite materials?

It is used in composite materials as a reinforcement layer, providing enhanced strength, stability, and resilience to the final product. By integrating non-woven polyester into composite matrices, manufacturers can exploit its uniform fiber distribution to achieve consistent mechanical properties across the composite part. This reinforcement is particularly valuable in applications requiring lightweight, yet durable materials, as it significantly improves impact resistance, tensile strength, and flexibility. Its compatibility with various resin systems also makes non-woven polyester a versatile choice for composite manufacturing, enabling its use in automotive, marine, construction, and aerospace industries.

What are the main advantages of using non-woven polyester in composites?

The main advantages of using non-woven polyester in composites include its superior tensile strength, uniformity, and resistance to chemicals and physical wear. Unlike woven materials, non-woven polyester provides consistent reinforcement throughout the composite part, eliminating weak points and enhancing overall durability. Its excellent bond with resin systems improves the composite’s impact resistance and fatigue life. Additionally, non-woven polyester’s lightweight nature contributes to the production of lighter, more efficient products, making it an ideal choice for industries prioritizing performance and longevity.

Can it be used with all types of resin systems?

Yes, it is compatible with a wide range of resin systems, including polyester, epoxy, and vinyl ester resins. Its versatility and ease of impregnation make it an excellent choice for various composite manufacturing processes, from hand lay-up to resin infusion and pultrusion. The adaptability of non-woven polyester to different resins allows for its use in a diverse array of applications, offering manufacturers the flexibility to select the most appropriate resin system for their specific performance requirements.

How does non-woven polyester compare to woven fabrics in composite reinforcement?

Compared to woven fabrics, non-woven polyester offers superior uniformity and multidirectional strength, making it ideal for applications requiring consistent performance across the entire composite part. While woven fabrics provide strength in the direction of the weave, non-woven polyester distributes its reinforcement evenly, eliminating the risk of delamination and stress concentration. This leads to improved impact resistance and durability. Additionally, non-woven polyester’s ease of handling and cutting can simplify the manufacturing process, reducing material waste and production time.

What applications are most suitable for non-woven polyester reinforcements?

They are most suitable for applications requiring lightweight, durable materials with consistent mechanical properties. This includes automotive components, marine hulls, wind turbine blades, and construction panels. Its resistance to environmental factors also makes non-woven polyester ideal for outdoor and high-wear applications. The material’s adaptability to various resin systems and manufacturing processes further broadens its applicability, making it a valuable asset in the production of high-performance composite parts.

How does it affect the mechanical properties of composites?

It significantly enhances the mechanical properties of composites, including tensile strength, impact resistance, and flexibility. Its uniform fiber distribution ensures even stress distribution, reducing the likelihood of failure under load. It also improves the composite’s resistance to cracking and fatigue, extending the lifespan of the final product. By reinforcing the matrix material, non-woven polyester contributes to a higher strength-to-weight ratio, a critical factor in many engineering and design applications.

Can it be used in both thermoset and thermoplastic composite processes?

Yes, it can be used in both thermoset and thermoplastic composite processes. Its compatibility with a wide range of resin systems makes it a versatile choice for reinforcing thermoset composites, where it enhances structural integrity and performance. In thermoplastic composites, it can be incorporated to improve tensile strength and impact resistance, contributing to the development of robust, lightweight materials suitable for a variety of industrial applications. This flexibility allows manufacturers to leverage the benefits of non-woven polyester across different composite manufacturing technologies, optimizing their products for performance and efficiency.