Glass Fiber Reinforcements

Glass fibre reinforcement is a critical component in composite materials, offering a combination of high strength, durability, and flexibility. This reinforcement material is made from extremely fine fibers of glass and is used to strengthen composite products. Available in various forms such as woven fabric, chopped strand mat, and multiaxial fabrics, glass fibre reinforcement is versatile in its applications. The inclusion of glass fibres in a composite matrix, such as resin, significantly enhances the mechanical properties of the final product, making it stronger, more durable, and resistant to impact and fatigue. Its widespread use across industries underscores its effectiveness in providing structural integrity to composite materials.

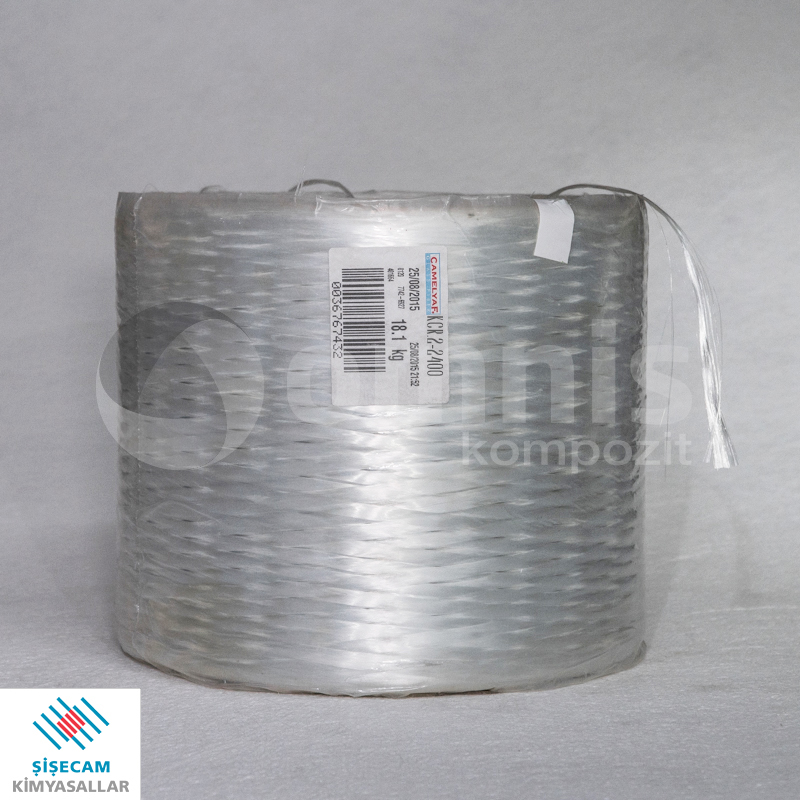

AR Glass Fiber Roving with High ZrO₂ Ratio

Review

Surface Tulle (Cortel)

Review

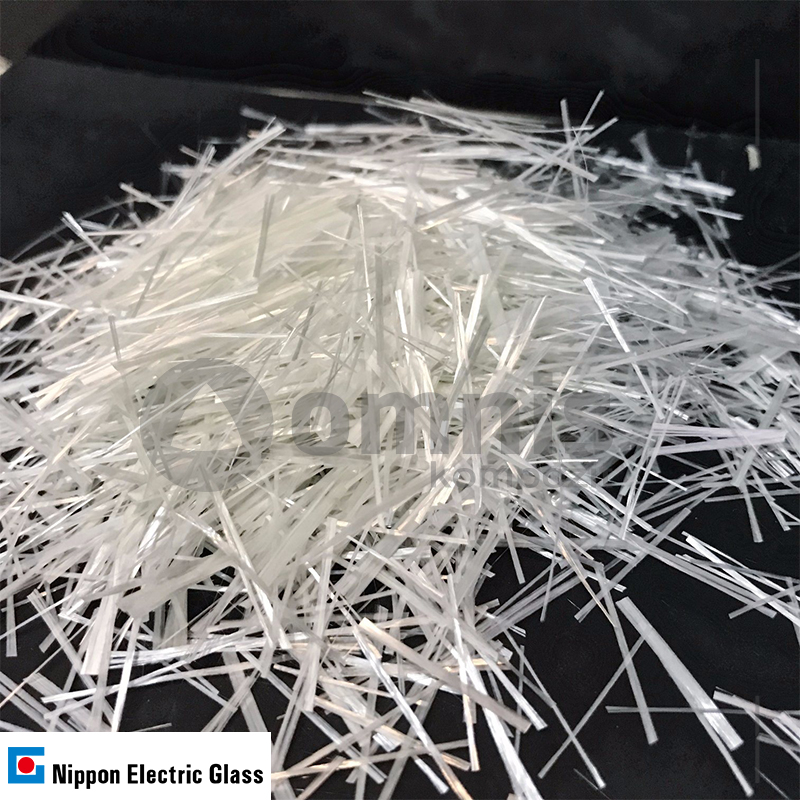

FibraTec V12 Trimming AR Glass Fiber

Review

High ZrO₂ Ratio AR Glass Fiber Trimming

Review

Glass Fiber Trimming (Taiwan Glass)

Review

Glass Fiber Trimming (Şişecam)

Review

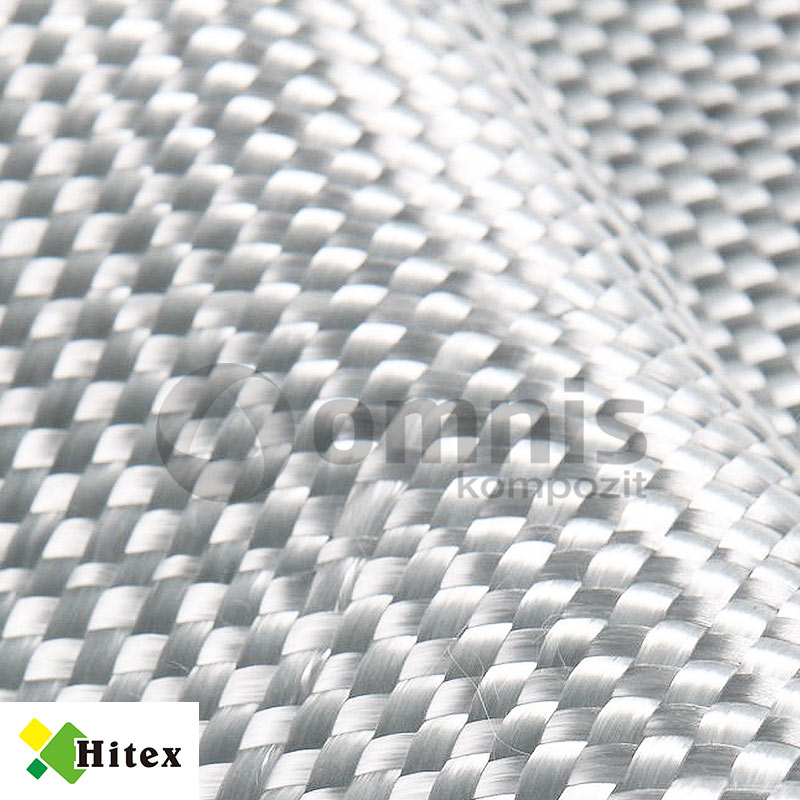

Glass Fiber Ribbon Weaving

Review

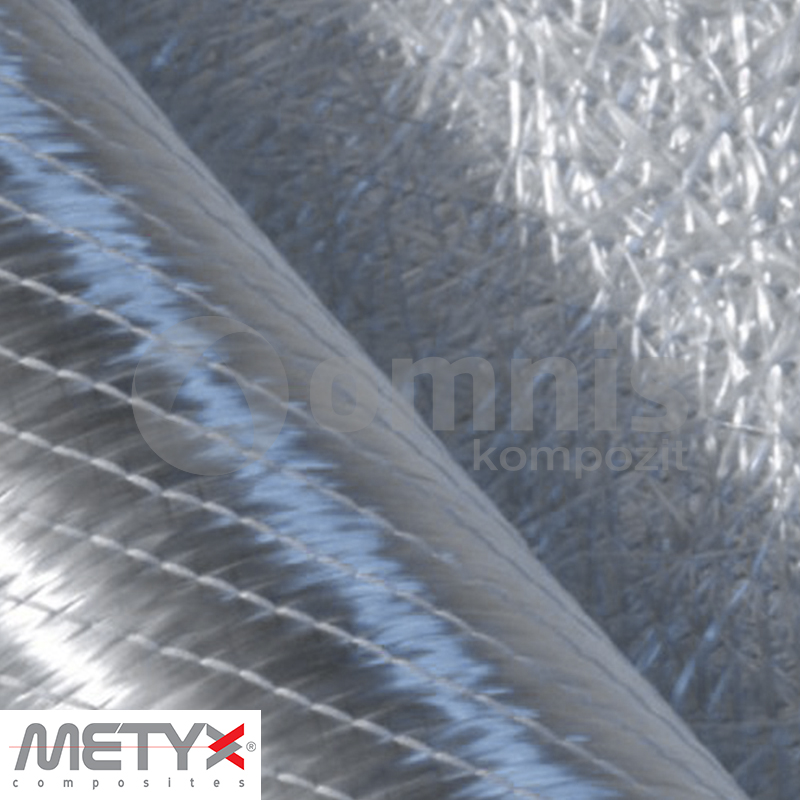

Multiaxial Glass Fiber Fabrics

Review

Metycore RTM Fiber

Review

Glass Fiber Weaving

Review

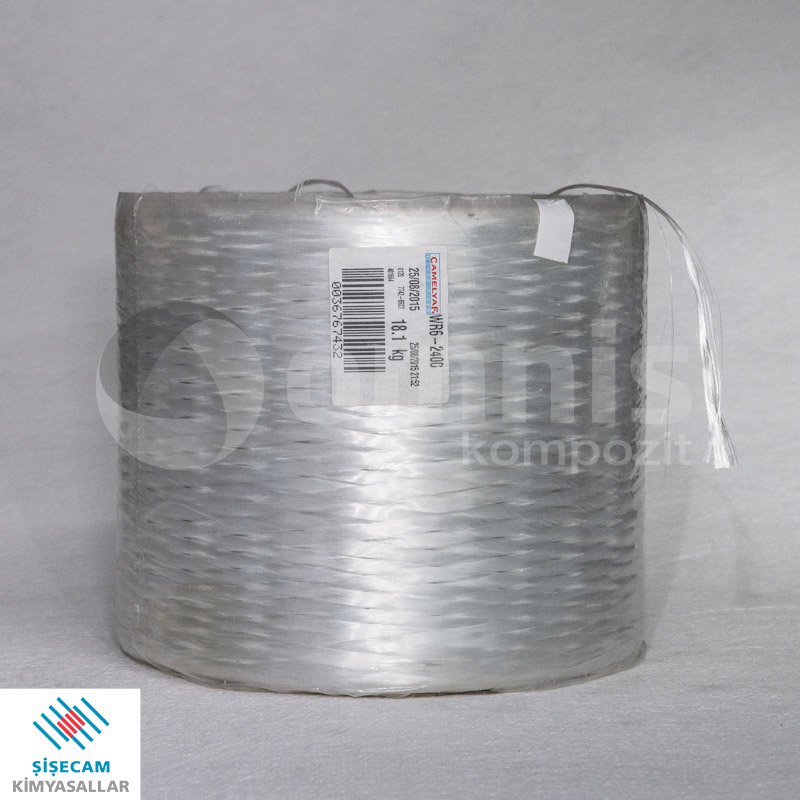

Multi-End Trimmable Glass Fiber Roving

Review

Single-ended Glass Fiber Roving

Review

LFT Compatible Single End Glass Fiber Roving for Thermoplastic Resins

Review

Continuous Felts from Continuous Fibers

Review

Low Grammage Glass Fiber Felt

Review

General Purpose Glass Fiber Felt

ReviewHow is glass fibre produced for reinforcement purposes?

Glass fibre for reinforcement purposes is produced by drawing molten glass through fine nozzles, creating continuous filaments that are then cooled and bundled together. These filaments can be further processed into various forms, including chopped glass fiber, woven fabric, and multiaxial fabrics, depending on the application requirements. The production process is carefully controlled to achieve fibers of specific diameters and properties, ensuring optimal performance in reinforcement applications. The versatility of glass fibre production allows for the creation of a wide range of reinforcement products, including surface veils and chopped strand mats, catering to diverse composite manufacturing needs.

What are the key benefits of using glass fibre reinforcement in composites?

The key benefits of using glass fibre reinforcement in composites include enhanced strength, durability, and resistance to environmental factors. Glass fibre reinforcements, such as woven fabric and chopped strand mat, provide composites with improved tensile strength, impact resistance, and flexibility. They also offer excellent resistance to corrosion, moisture, and temperature variations, making them suitable for outdoor and harsh environmental applications. Additionally, glass fibre reinforcements are cost-effective compared to other reinforcement materials, offering a balanced combination of performance and affordability. Their versatility and compatibility with various resin systems further enhance their appeal across a wide range of industries.

How do glass fibre reinforcements compare to carbon fibre reinforcements?

Glass fibre reinforcements and carbon fibre reinforcements each have unique properties that make them suitable for different applications. Glass fibre, including forms like woven fabric and chopped strand mat, offers good strength, flexibility, and resistance to environmental damage at a lower cost than carbon fibre. It is also less brittle, making it more suitable for applications requiring impact resistance. Carbon fibre, on the other hand, provides superior strength-to-weight ratios and stiffness, making it ideal for high-performance applications where weight reduction is critical. The choice between glass and carbon fibre reinforcements depends on the specific requirements of the project, including mechanical properties, cost considerations, and environmental exposure.

In what applications is glass fibre reinforcement most commonly used?

Glass fibre reinforcement is commonly used in a wide range of applications, including automotive parts, marine vessels, construction materials, and sporting goods. Its versatility is evident in products such as boat hulls, automotive body panels, wind turbine blades, and surfboards, where the benefits of woven fabric, chopped strand mat, and multiaxial fabrics are utilized. Glass fibre’s excellent strength-to-weight ratio, durability, and cost-effectiveness make it a preferred choice for reinforcing composite materials in both structural and non-structural components across various industries.

Can glass fibre reinforcement be used in outdoor applications?

Yes, glass fibre reinforcement can be used in outdoor applications due to its excellent resistance to environmental factors. Products like surface veil and woven fabric provide composites with protection against UV radiation, moisture, and temperature fluctuations, making them ideal for outdoor use. Glass fibre reinforced composites are commonly found in applications such as marine vessels, outdoor sporting equipment, and construction materials, where durability and resistance to weathering are essential. The inherent properties of glass fibre reinforcements ensure long-lasting performance and reliability in challenging outdoor environments.

What types of resins are compatible with glass fibre reinforcements?

Glass fibre reinforcements are compatible with a wide range of resin systems, including polyester, epoxy, vinyl ester, and phenolic resins. The choice of resin depends on the specific requirements of the application, such as mechanical strength, chemical resistance, and thermal stability. Polyester resins are commonly used for their cost-effectiveness and ease of handling, making them suitable for general-purpose applications. Epoxy resins offer superior mechanical properties and adhesion, ideal for high-performance applications. Vinyl ester and phenolic resins provide excellent chemical and fire resistance, respectively. The compatibility of glass fibre reinforcements with various resins enhances their versatility in composite manufacturing.

How does glass fibre reinforcement impact the strength and durability of a composite?

Glass fibre reinforcement significantly impacts the strength and durability of a composite by providing high tensile strength, impact resistance, and stiffness. The incorporation of glass fibres, such as woven fabric or chopped strand mat, into a resin matrix distributes loads more evenly across the material, enhancing its overall structural integrity. This reinforcement also improves the composite’s resistance to cracking, fatigue, and environmental degradation, extending its lifespan. The durability and performance of glass fibre reinforced composites make them ideal for demanding applications where reliability and longevity are critical.

What are the environmental considerations of using glass fibre reinforcement?

The environmental considerations of using glass fibre reinforcement include the energy-intensive production process and challenges associated with recycling. While glass fibre reinforcements, such as woven fabric and chopped strand mat, provide significant benefits in composite materials, their production requires high temperatures, leading to considerable energy consumption. Recycling glass fibre reinforced composites can be complex due to the difficulty of separating the fibre from the resin matrix. However, ongoing research and development efforts aim to improve the recyclability of these materials and reduce their environmental impact, focusing on sustainable manufacturing practices and end-of-life disposal options.

How do I choose the right type of glass fibre reinforcement for my project?

Choosing the right type of glass fibre reinforcement for your project involves considering the specific mechanical properties, environmental exposure, and processing requirements of the application. Evaluate the strength, stiffness, and impact resistance needed, as well as compatibility with the chosen resin system. For structural applications requiring high tensile strength, woven fabric or multiaxial fabrics may be ideal. Chopped strand mat or chopped glass fiber could be more suitable for complex shapes or parts requiring uniform strength in all directions. Surface veil is often used for improved surface finish and environmental resistance. Consulting with material specialists and conducting tests can help determine the most appropriate glass fibre reinforcement for achieving optimal performance in your composite project.