Fiber Reinforcements

Fiber-reinforced composite (FRP) reinforcement is a cutting-edge technology designed to enhance the strength and durability of structures. This innovative material combines the flexibility of fibers with a polymer matrix, resulting in a reinforcement solution that is both lightweight and incredibly strong. Fiber-reinforced composite is revolutionizing the construction industry, offering an alternative to traditional materials with its exceptional properties. Its versatility allows it to be used in a wide range of applications, from bridges and buildings to marine and industrial projects. By choosing FRP reinforcement for your construction needs, you're investing in a future where your projects stand the test of time, showcasing unparalleled resilience and innovation.

Basalt Single End Roving

View Product

Basalt Fiber Trimming

View Product

AR Glass Fiber Roving with High ZrO₂ Ratio

View Product

Linen Fiber Woven Fabric

View Product

UD (Unidirectional) Linen Fiber Prepreg Strip

View Product

Linen Fiber Woven Prepreg

View Product

UD (Unidirectional) Linen Fiber Prepreg

View Product

Aramid Fiber Trimming

View Product

Aramid Fiber Woven Fabric

View Product

Carbon Fiber Trimming

View Product

Carbon Fiber Ribbon

View Product

Multiaxial Carbon Fiber Fabric

View Product

Carbon Fiber Woven Fabric

View Product

Surface Tulle (Cortel)

View Product

FibraTec V12 Trimming AR Glass Fiber

View Product

High ZrO₂ Ratio AR Glass Fiber Trimming

View Product

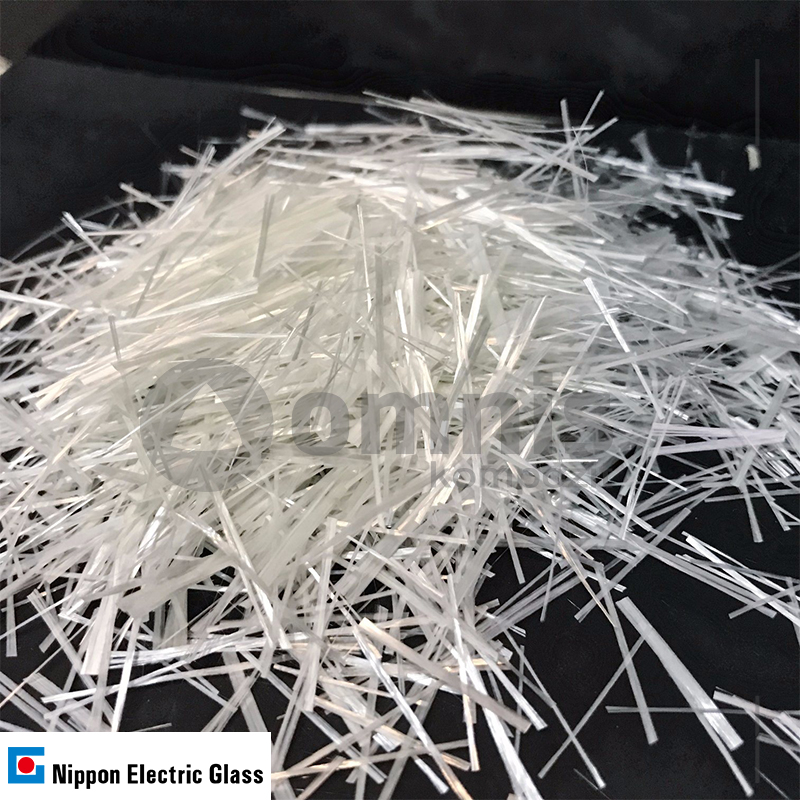

Glass Fiber Trimming (Taiwan Glass)

View Product

Glass Fiber Trimming (Şişecam)

View Product

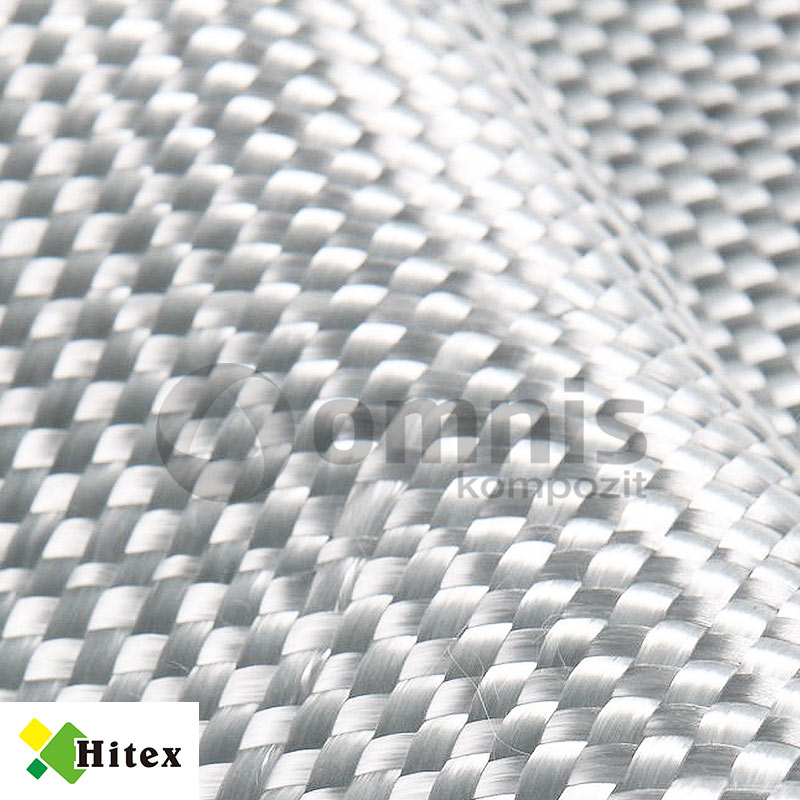

Glass Fiber Ribbon Weaving

View Product

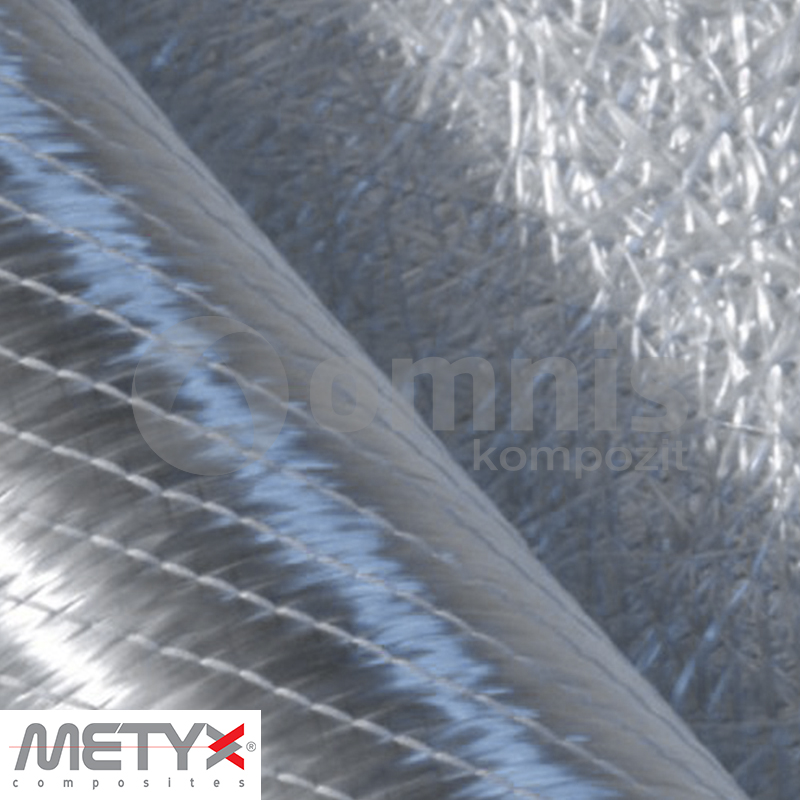

Multiaxial Glass Fiber Fabrics

View Product

Metycore RTM Fiber

View Product

Glass Fiber Weaving

View Product

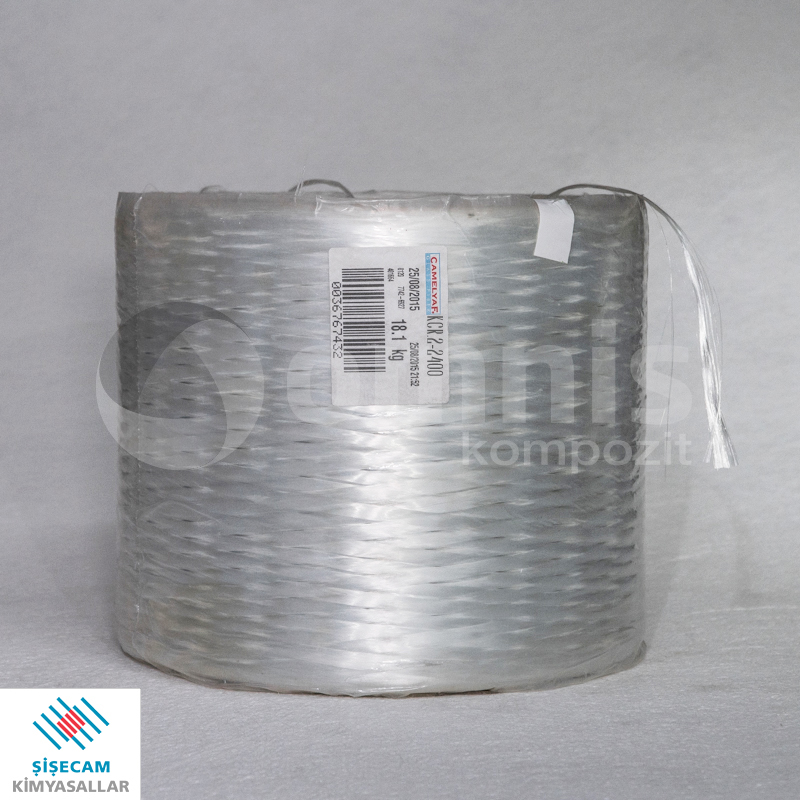

Multi-End Trimmable Glass Fiber Roving

View Product

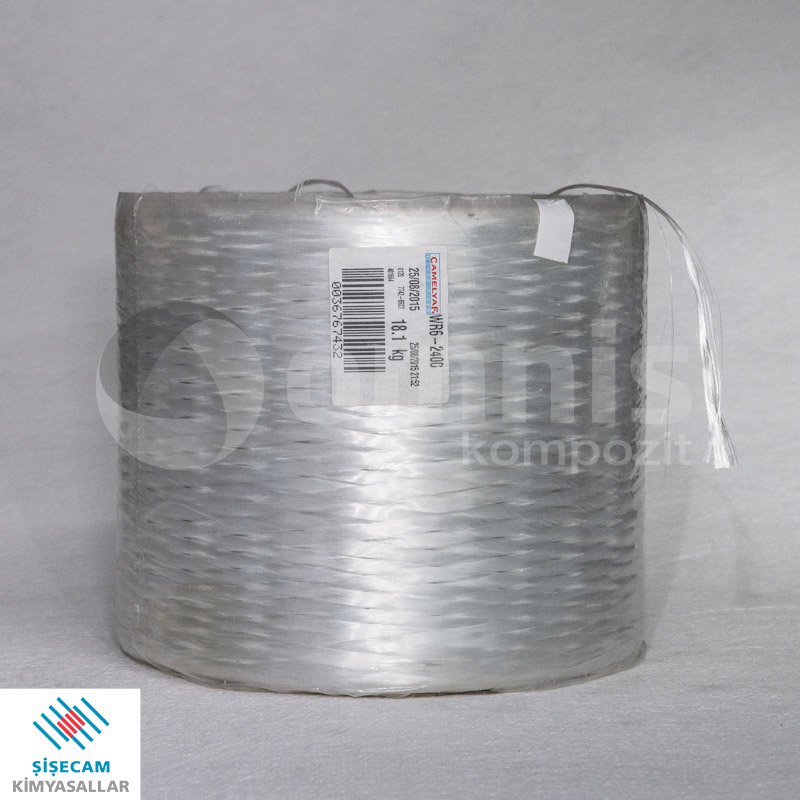

Single-ended Glass Fiber Roving

View Product

LFT Compatible Single End Glass Fiber Roving for Thermoplastic Resins

View Product

Continuous Felts from Continuous Fibers

View Product

Low Grammage Glass Fiber Felt

View Product

General Purpose Glass Fiber Felt

View ProductHow does FRP reinforcement compare to traditional reinforcement materials?

FRP reinforcement offers a compelling alternative to traditional reinforcement materials like steel, thanks to its unique properties. Unlike steel, FRP reinforcement does not corrode, making it ideal for use in environments prone to moisture or chemical exposure. It’s significantly lighter, facilitating easier handling and installation while maintaining superior strength. This innovative material also boasts excellent fatigue resistance and can be tailored to suit specific strength and stiffness requirements. By integrating FRP reinforcement into construction projects, engineers and architects can overcome the limitations of traditional materials, paving the way for more durable, efficient, and innovative structures.

What are the main benefits of using fiber-reinforced composite in construction?

The use of fiber-reinforced composite in construction brings numerous benefits, chief among them being its exceptional strength-to-weight ratio. This property allows for the design of lighter structures without compromising on durability or safety. Additionally, FRP reinforcement is highly resistant to corrosion, making it an ideal choice for projects exposed to harsh environmental conditions. Its flexibility in design and application enables the creation of complex shapes and sizes, offering architects and engineers greater creative freedom. Moreover, the longevity and low maintenance requirements of FRP reinforcement result in significant cost savings over the lifespan of a project. By choosing FRP reinforcement, you’re not just building for today but investing in the sustainability and resilience of your structures for years to come.

Can fiber-reinforced composite be used in all types of construction projects?

FRP reinforcement is incredibly versatile and can be used in a wide array of construction projects, ranging from residential and commercial buildings to infrastructure such as bridges and tunnels. Its adaptability to different environmental conditions and design requirements makes it suitable for both new constructions and the rehabilitation of existing structures. However, the specific characteristics of each project, such as load requirements and exposure conditions, should be carefully considered when selecting fiber-reinforced composite. Consulting with experts and conducting thorough planning ensures that fiber-reinforced composite is utilized effectively, maximizing its benefits for any given project.

How do I choose the right type of FRP reinforcement for my project?

Choosing the right type of fiber-reinforced composite for your project involves a detailed analysis of the project’s specific requirements, including structural loads, environmental conditions, and design objectives. Different types of FRP reinforcement, such as carbon, glass, or aramid fibers, offer varying properties in terms of strength, stiffness, and resistance to environmental factors. Consulting with manufacturers and specialists in fiber-reinforced composite can provide valuable insights into the most suitable options for your project. Additionally, considering the long-term performance and maintenance requirements will ensure that the selected FRP reinforcement meets both current and future needs of the structure.

What are the installation procedures for FRP reinforcement?

The installation of fiber-reinforced composite requires careful planning and execution to ensure optimal performance. The process typically involves preparing the surface, cutting the FRP material to the required dimensions, and then securing it in place using appropriate bonding agents or mechanical fasteners. For concrete applications, the surface must be clean and roughened to ensure a strong bond. It’s crucial to follow the manufacturer’s guidelines and recommendations for installation to achieve the desired structural integrity. Professional training or consultation with experts in fiber-reinforced composite can also enhance the installation process, ensuring that the reinforcement is applied effectively and safely.

How does the cost of FRP reinforcement compare to steel reinforcement?

Initially, the cost of FRP reinforcement may be higher than that of traditional steel reinforcement. However, when considering the total lifecycle costs, FRP reinforcement often proves to be more economical. Its superior durability, resistance to corrosion, and lower maintenance requirements contribute to significant savings over time. Additionally, the lightweight nature of fiber-reinforced composite can reduce transportation and handling costs, as well as accelerate the construction process. When evaluating the cost-effectiveness of fiber-reinforced composite, it’s essential to consider these long-term benefits and savings, making it a wise investment for many construction projects.

What are the longevity and durability aspects of FRP reinforcement?

FRP reinforcement is renowned for its longevity and durability. Its resistance to corrosion, fatigue, and environmental wear and tear means it can maintain its structural integrity and performance for decades, far surpassing traditional materials in terms of lifespan. This makes FRP reinforcement an ideal choice for projects where long-term durability is a priority, such as in harsh environmental conditions or in structures requiring minimal maintenance. The initial investment in fiber-reinforced composite pays off through reduced repair and replacement costs, ensuring that structures remain safe, functional, and aesthetically pleasing for many years.

Can FRP reinforcement be customized for specific project needs?

Yes, one of the significant advantages of fiber-reinforced composite is its ability to be customized for specific project needs. Manufacturers can tailor the material’s properties, such as its strength, stiffness, and resistance to environmental factors, to meet the unique requirements of each project. This customization extends to the size, shape, and orientation of the fibers, allowing for a high degree of flexibility in design and application. Whether you’re working on a complex architectural structure or a simple infrastructure project, FRP reinforcement can be engineered to provide optimal performance and efficiency, making it a versatile solution for a wide range of construction challenges.