AR Glass Fiber Roving with High ZrO₂ Ratio

Category: Concrete Systems

Brand: HUIERJIE, NIPPON ELECTRIC GLASS

GRC (glass fiber reinforced concrete) is formed by reinforcing a high-performance cement-based composition with “alkali resistant glass fibers”. AR (alkali resistant) glass fiber, thanks to the Zirconium (ZrO2) on it, provides resistance against alkali and acid resistance in cement content and acts as reinforcement without melting in cement. Alkali-resistant glass fiber provides increased strength by preventing the spread of cracks in concrete. It also offers high tensile strength as well as the compressive strength of normal concrete. Fiber has 3 times the strength and 4 times the flexibility of steel. In addition, since alkali-resistant glass fiber does not corrode, it preserves itself for many years without deterioration. Alkali resistant glass fiber is applied on the mold using spraying machines by trimming at the same time with the GRC concrete mix. In production by spraying method, 3.5% of the weight of glass fiber should be added to reach optimum strength values. Before starting the spraying process, a suitable mold release agent should be applied to the mold surface to remove the part from the mold surface easily. After each coat of spraying, the air should be removed from the mixture with a spring roller suitable for GRC. In addition, measuring the thickness after each coat with a thickness gauge allows for the production of appropriate thicknesses.

Benzer Ürünler

Multiaxial Glass Fiber Fabrics

Ürünü İncele

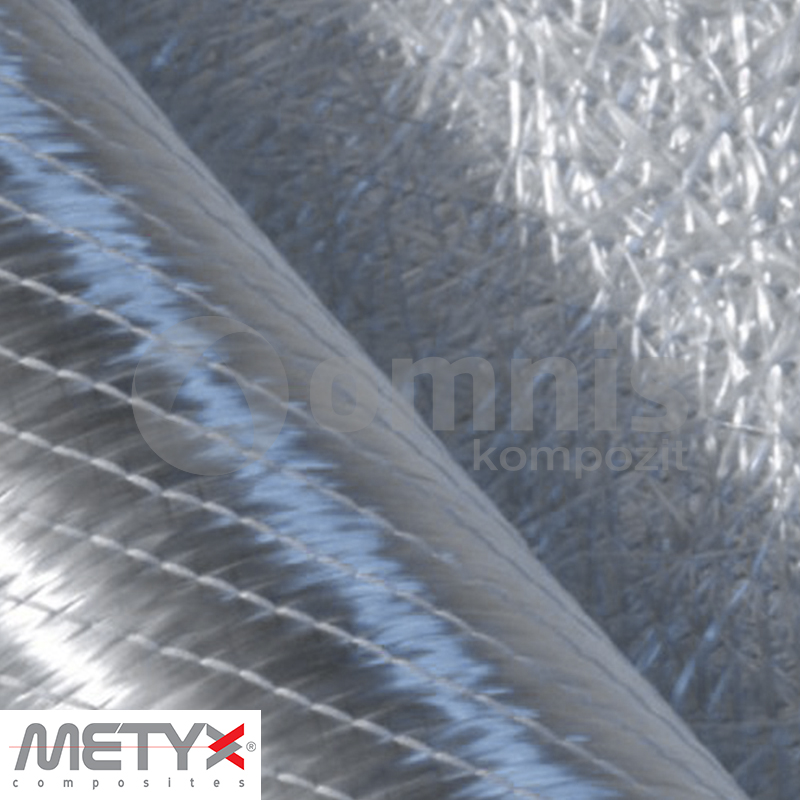

Continuous Felts from Continuous Fibers

Ürünü İncele

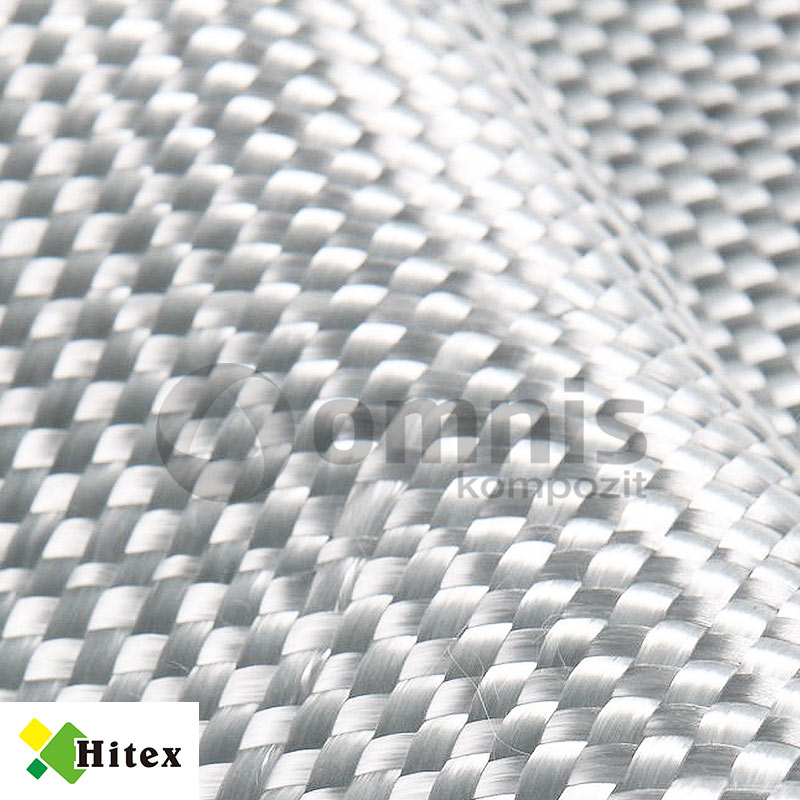

Glass Fiber Weaving

Ürünü İncele

Single-ended Glass Fiber Roving

Ürünü İncele