Vacuum Bag

Vacuum Bag

Ürünü İnceleWhat is a Vacuum Bag?

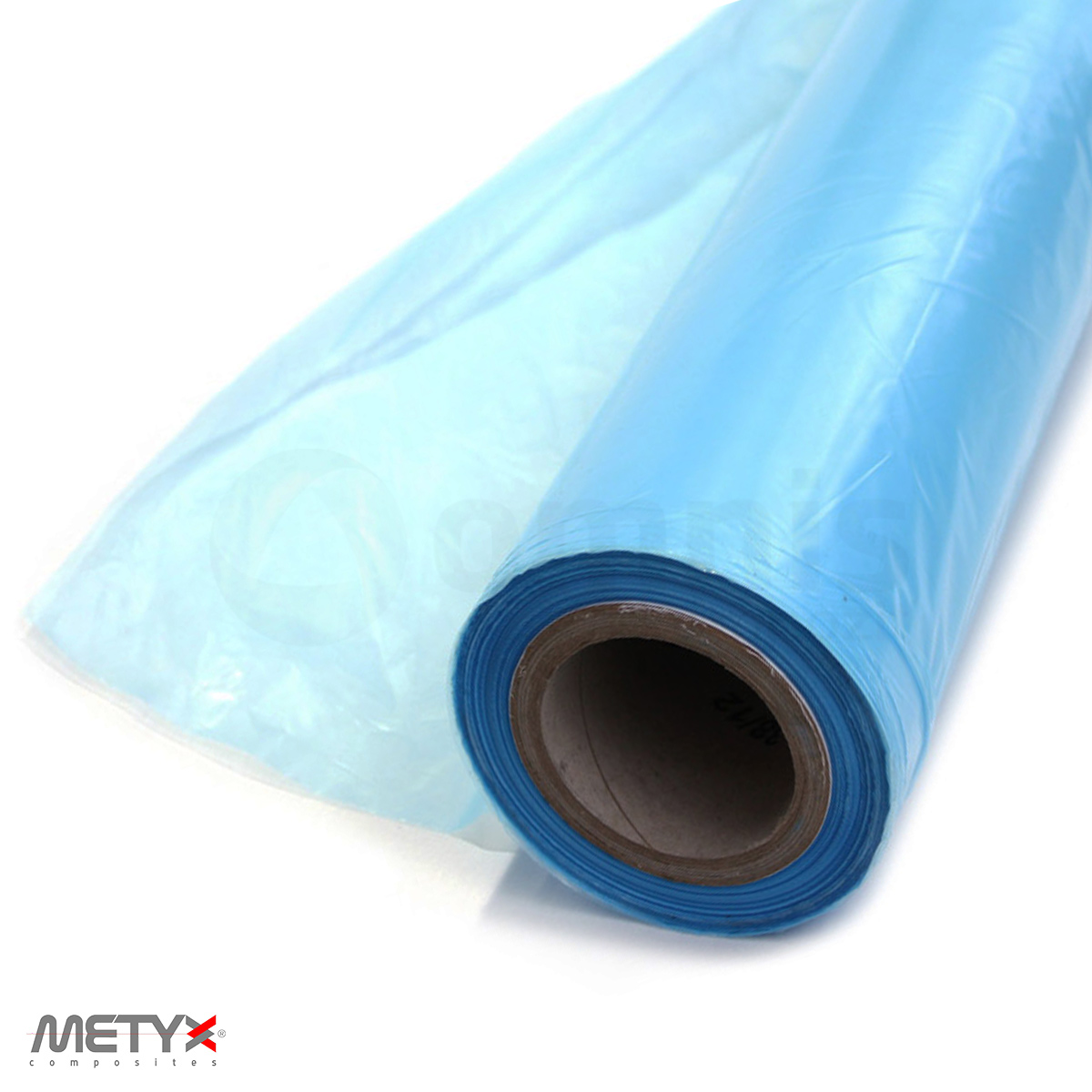

Vacuum bagging is also called vacuum bagging film. This material, which attracts attention with its durable structure, is blue in color and 65 microns thick. Thanks to its superior properties, it offers a robust performance even at high temperatures of up to 170 °C.

It has a multi-purpose use as it is ideal for professional and industrial use. In this way, it helps to complete certain applications efficiently. In addition, it provides quality materials in composite manufacturing with its high durability and structural properties. With its superior qualities and usefulness, this material offers a safe and ideal use in industrial areas. It stands out with its high temperature resistance feature, helping to achieve efficient results in the protection of materials and in some heat-requiring applications.

In Which Areas is Vacuum Bag Used?

The vacuum bag is a material used in a wide range of application methods. The main reason why it is preferred in different applications is its versatility and effectiveness. The areas of use of this material are as follows:

Aviation

Consumer Recreation

Ballistics/Defense Industry

Industrial Projects

Maritime

Transportation

Wind Energy

Infrastructure Projects

What is Vacuum Bag Molding?

Vacuum bag molding is a method used in the production of composite materials. Thanks to this method, products are produced and shaped more effectively. It is used in the production of composite materials as well as in the manufacture of fiber reinforced plastics (FRP).

Fiber-reinforced materials placed on a mold are covered with this bag and the materials are compressed on the mold surface. This process defines the vacuum bag molding process. During the process, this bag is applied on the materials to be molded and air is prevented. Through this process, a pressure is created under vacuum. This pressure allows the materials to settle more smoothly and homogeneously on the mold surface.

Vacuum Bag Features

The general features of the vacuum bag product are as follows:

Micro thickness is 75.

2.5 (double layer, 4.6 m when unfolded) roll width.

For the 65 micro thickness option, the roll width is 3 m (double layer, 6 m when unfolded).

Traditional vacuum bagging is used in a variety of applications such as prepreg and resin infusion.

Resistant up to 170 degrees.

It is multi-layered and general purpose.

Thanks to these features, it offers a convenient use for various application methods. In general, the basic functions of this material in the application methods used are as follows:

Prepreg: In the prepreg application method, this bag is used inside or outside the autoclave. This intended use compresses textile or composite materials previously saturated with resin. The prepreg method is preferred in the production process of high-strength and lightweight composite materials.

Wet-laid vacuum bagging: This application method allows the bag to be applied onto the material with the resin in liquid form and then compressed under vacuum. The resin is evenly distributed on the surface of the material thanks to this method. Thus, quality and low-cost products are obtained.

Resin infusion: In the resin infusion method, the function of this bag is to impregnate the resin on the material to be coated with the help of vacuum. In this method, the bag ensures homogeneous resin distribution on the surface and helps to obtain quality materials. The resin infusion method using this bag is mainly used in the manufacture of composite materials.

Glass lamination: This bag is used in this method by combining glass fibers and resin material. It enables the production of durable, strong and lightweight glass composite materials.

Vacuum bonding/coating: This method is used to join two or more materials. Air gaps between the materials are minimized with the help of this bag. This results in a more durable bonding and coating.