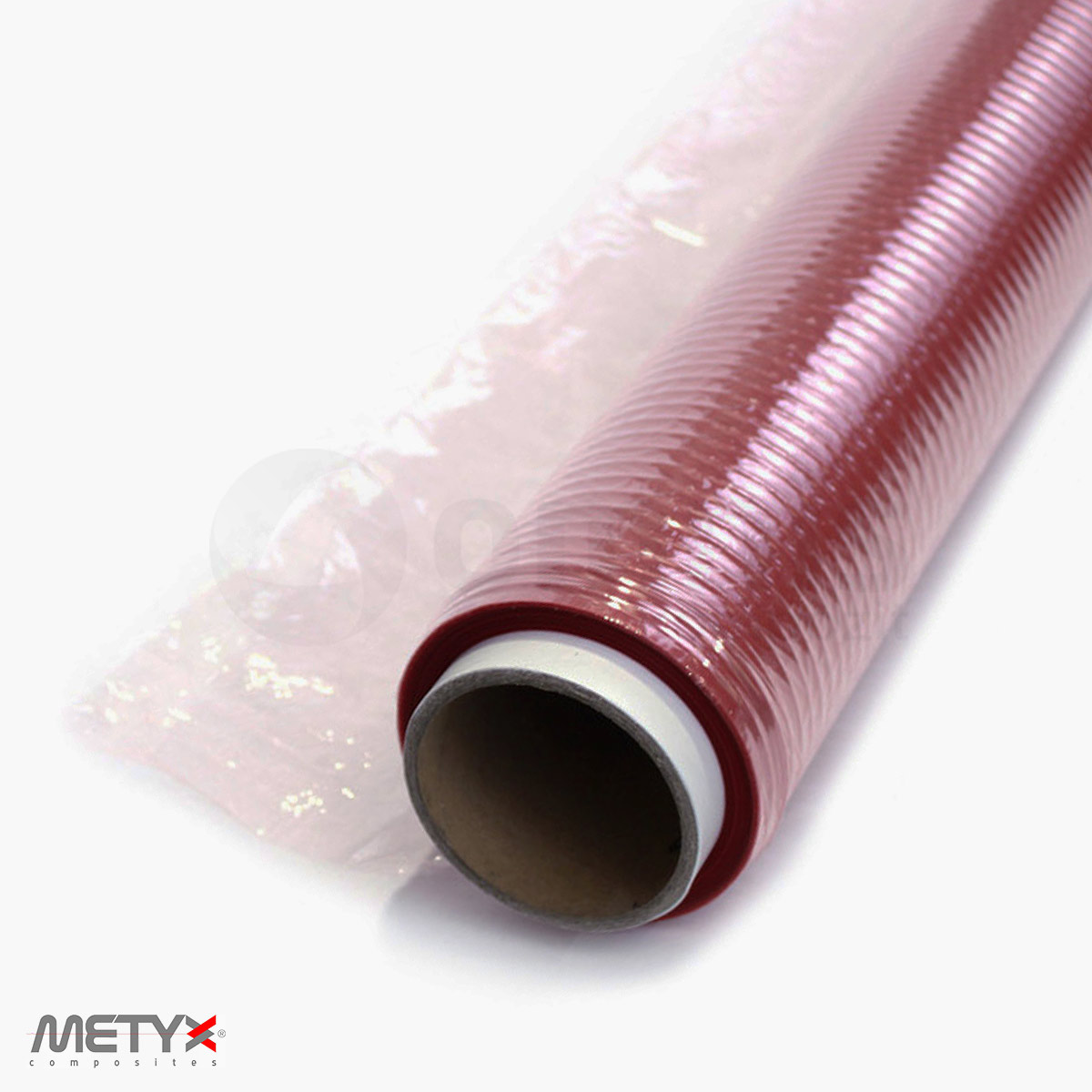

Release Film

Perforated Release Film

Ürünü İnceleWhat is a Release Film?

Vacuum infusion is the wetting of dry fibers laid in the mold with resin under vacuum pressure. Choosing the appropriate resin and fiber is an important step in infusion methods. In addition, the right consumables must also be used. Separator Film is among the consumables used in this production method.

This film is placed between the mold and the composite material during the vacuum infusion process and acts as a barrier. This material prevents the resin from sticking to the mold surface and also facilitates resin absorption. In this way, the composite part produced can be removed more easily. Thus, mold cleaning is also easier.

What Does Perforated Release Film Do?

Perforated release film is a material also called perforated nylon. This material is used in vacuum infusion and bagging processes. It is also a vacuum infusion consumable used with fiber reinforcements and epoxy resins. It is usually orange in color. It gives superior results when used with different resin types. In particular, polyester, vinylester and epoxy resins can be used together as they are compatible with this film.

Perforated release film is a useful material for vacuum bagging and infusion methods. It can also be used in the hand laying method. It provides convenience in vacuum applications by enclosing the vacuum nylon into the entire mold and placing it on the mold. The features of this product are as follows:

Specially designed to prevent adhesion with resin.

It is used as the first barrier between composite laminate and vacuum bagging materials.

Roll width is 145 cm.

Its thickness is 25 microns.

P3 Perforated and can withstand temperatures up to 120 °C.

In general, the uses of these film types include:

Aviation The use of lightweight and durable composite products is also becoming common in the aerospace industry. Aircraft wings and other parts are made of composite products. For this reason, the vacuum infusion method is preferred in the production of products. Perforated separator films, which play a major role in this method, are also used at this time.

Marine Most of the composite materials commonly used in yacht and boat manufacturing are produced by a vacuum infusion process. Perforated films ensure homogeneous and durable parts in the production of marine vehicles.

Automotive: Composite materials are important products that add lightness and dynamism to the automotive industry. The vacuum infusion process is used to produce lightweight and strong parts. Perforated films are used in this process.

Wind energy: Vacuum infusion is used in important structures such as the blades of wind turbines. Perforated films, one of the indispensable materials of this method, are included in these structures as part of the process.

Space and aerospace: Lightweight and strong materials are used for parts and components of spacecraft. The perforated films used in the vacuum infusion method enable parts of this nature to be produced.

Sports equipment: These films are part of the production process of composite materials used in sports equipment. Especially skateboards, rackets and snowboards are among the sports equipment where these materials are used.