Mold Release Agents

Mold release agents are specialized substances applied to mold surfaces to ensure the easy and damage-free release of products from molds. These agents, including various forms of release oils, create a barrier between the mold and the material being formed, preventing sticking and facilitating a smooth release. Utilizing high-quality mold release agents is essential for maintaining the integrity of both the mold and the manufactured products, optimizing production efficiency, and achieving superior surface finishes.

D-32 Liquid Paraffin

View Product

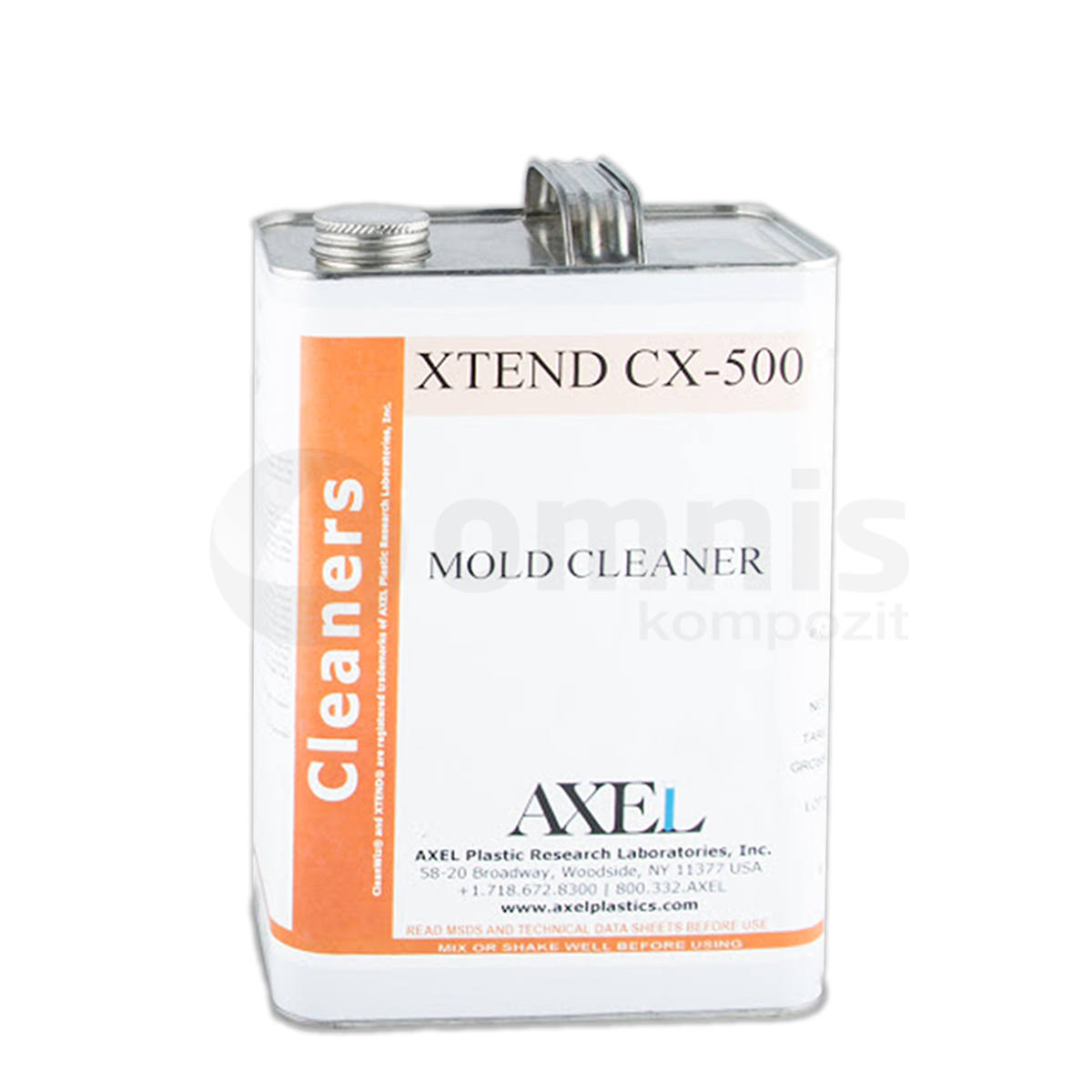

Mold Cleaner

View Product

Mold Liner

View Product

Semi-Permanent Mold Release Agents

View Product

Spray Mold Release Agents

View Product

Liquid PVA Mold Release Agents

View Product

Mold Release Waxes

View ProductHow do mold release agents work?

Mold release agents work by forming a thin, lubricative layer on the surface of molds. This layer significantly reduces the adhesion between the mold and the material, allowing for a seamless separation after the material has set or cured. Release oils, in particular, are designed to withstand the pressures and temperatures of the molding process, ensuring that the release agent remains effective throughout. The choice of a mold release agent is crucial for ensuring a smooth, efficient production process and high-quality final products.

What are the main types of mold release agents available?

The main types of mold release agents available include water-based, solvent-based, and silicone-based formulations, each catering to specific molding processes and materials. Water-based agents are environmentally friendly and ideal for applications requiring a clean, residue-free finish. Solvent-based agents offer excellent performance across a wide range of temperatures and materials. Silicone-based mold release agents, known for their versatility, provide a high-quality release for the most demanding applications. Selecting the right type of release oil or agent is key to achieving optimal results in your molding operations.

Can mold release agents be used with all types of molds and materials?

Yes, mold release agents can be used with a wide variety of molds and materials, including plastics, rubbers, composites, and metals. However, the effectiveness of a mold release agent, including specific formulations of release oil, depends on its compatibility with the mold material and the product being manufactured. It’s essential to select a mold release agent that is specifically designed for your application to ensure efficient release and high-quality finishes.

How do I choose the right mold release agent for my application?

Choosing the right mold release agent for your application involves considering the material of the mold, the product being manufactured, the desired surface finish, and the temperature and pressure conditions of the molding process. It’s important to select a release oil or agent that is compatible with these factors to ensure a smooth release and optimal product quality. Consulting with a specialist or testing different mold release agents under your specific production conditions can help identify the most effective solution for your needs.

Can mold release agents affect the surface finish of the final product?

Mold release agents can indeed affect the surface finish of the final product, but when chosen and applied correctly, they can enhance the appearance and quality of the surface. High-quality release oils are formulated to provide a smooth, defect-free finish, improving the aesthetics and functionality of the final product. It’s crucial to select and apply the mold release agent properly to achieve the desired surface finish while ensuring easy demolding.

Are there mold release agents suitable for high-temperature processes?

Yes, there are mold release agents specifically formulated to withstand high-temperature processes. These agents are designed to maintain their efficacy and stability at elevated temperatures, ensuring reliable mold release in applications such as metal casting and high-temperature plastics processing. Choosing a high-temperature compatible release oil or agent is essential for ensuring the integrity of both the mold and the product in these demanding conditions.

How are mold release agents applied to the mold surface?

Mold release agents are applied to the mold surface using various methods, including spraying, brushing, or wiping, depending on the agent’s formulation and the complexity of the mold. For uniform and efficient application, spraying is often preferred, especially for release oils, as it ensures even coverage and minimizes waste. Proper application technique is crucial for achieving optimal results, preventing defects, and extending the life of both the mold and the release agent.

How do I ensure even coverage when applying mold release agents?

Ensuring even coverage when applying mold release agents involves using the correct application method and equipment, such as spray systems designed for uniform distribution. It’s important to follow the manufacturer’s recommendations for application, including the amount of agent to use and the distance from the mold surface. Regular maintenance of application equipment and adherence to best practices can help achieve consistent coverage, ensuring effective release and high-quality product finishes.

Can the use of mold release agents improve the lifespan of molds?

Yes, the use of mold release agents can significantly improve the lifespan of molds in the casting process, whether for concrete, plastics, metals, or other materials. Mold release agents are substances applied to mold surfaces to prevent the material being cast from bonding to the mold, facilitating an easier release of the product from the mold. Their benefits extend beyond just facilitating the demolding process; they also play a crucial role in maintaining the integrity and extending the service life of molds. Here’s how mold release agents contribute to this:

1. Reduced Wear and Tear

Mold release agents create a protective barrier between the mold and the casting material. This barrier reduces the physical abrasion and chemical corrosion that molds can suffer from repeated use, especially when casting materials that may be abrasive or corrosive over time.

2. Prevention of Material Buildup

Continuous use of molds without release agents can lead to the buildup of casting material residues on the mold surface. Such buildup can not only damage the mold but also affect the quality of the products being cast. Release agents help in preventing this buildup, keeping molds clean and in good condition for longer periods.

3. Enhanced Surface Quality

By ensuring a clean and smooth release, mold release agents help in achieving a high-quality surface finish on the cast products. This reduces the need for post-processing, such as grinding or polishing, which can wear down the mold surface over time.

4. Reduced Cleaning Time and Effort

Molds treated with release agents typically require less effort to clean, as the release agent prevents material from adhering to the mold surface. This means that harsh cleaning methods, which can erode or damage the mold surface, are less frequently needed.

5. Increased Operational Efficiency

The smoother operation and reduced downtime for cleaning or repairing molds contribute to increased operational efficiency in the manufacturing process. This efficiency can indirectly contribute to the mold’s lifespan by minimizing instances of rough handling or excessive force that could damage the mold.