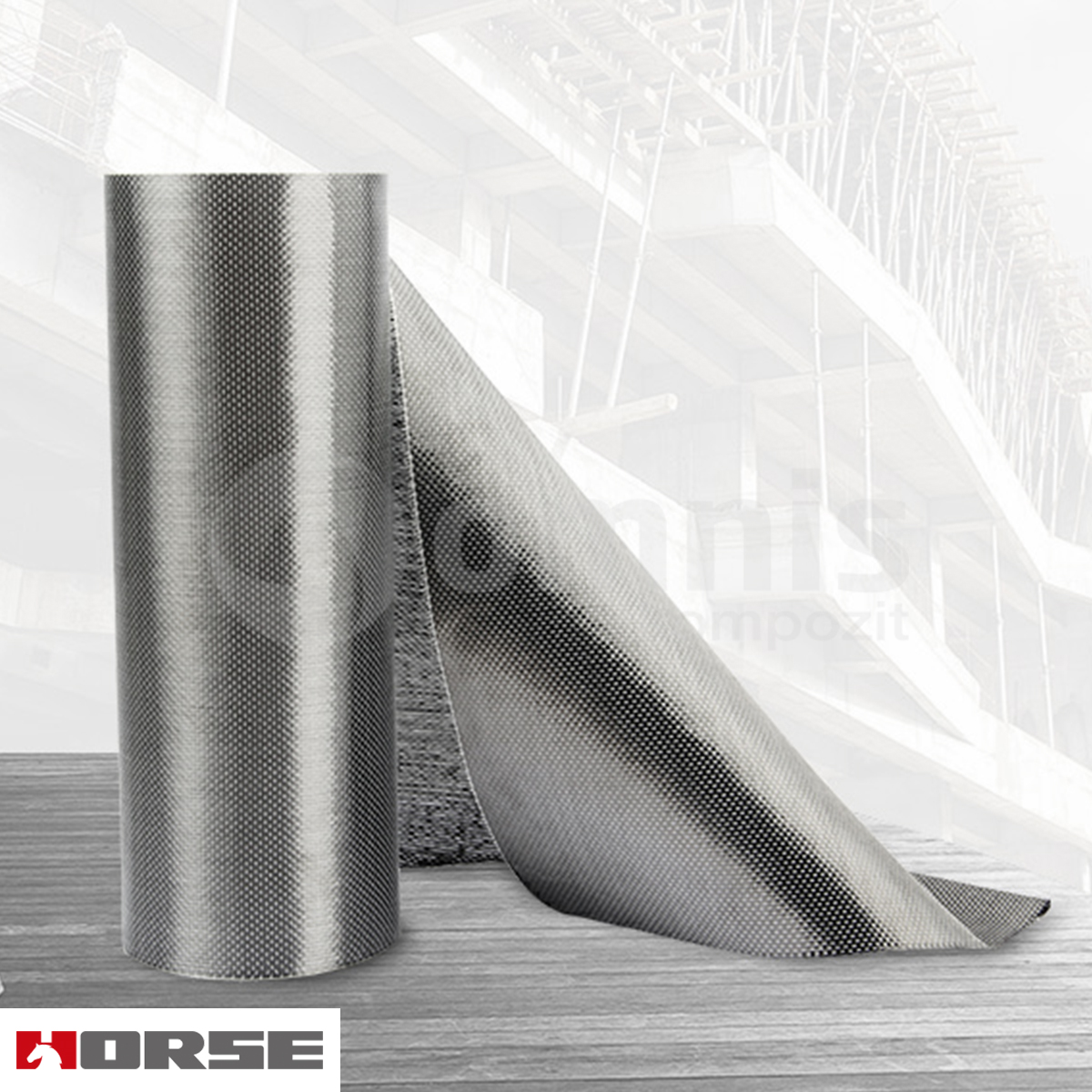

HORSE Carbon Building Reinforcement Systems

Carbon fiber structural reinforcement is a cutting-edge technology used to enhance the strength and durability of structures. It involves the application of carbon fiber reinforced polymer (CFRP) composites — materials known for their exceptional strength-to-weight ratio and corrosion resistance — to existing or new structures. This form of reinforcement is designed to fortify buildings, bridges, and other infrastructures against various stresses and strains, providing an effective solution for extending their service life and improving performance. Carbon fiber structural reinforcement is increasingly recognized as a vital component in modern construction and renovation projects, offering an innovative alternative to traditional reinforcement methods.

How does carbon fiber reinforcement enhance the strength of structures?

Carbon fiber reinforcement significantly enhances the strength of structures by providing additional tensile strength where it is most needed. When bonded to the surface of a structure, carbon fiber composites work to distribute loads more evenly, reducing stress concentrations and preventing the propagation of cracks. This reinforcement method is especially effective in areas subject to high tensile stresses, where traditional materials might fail. The inherent properties of carbon fiber, including its high stiffness and low weight, contribute to an increase in the structural integrity and load-bearing capacity of the reinforced structure, ensuring its longevity and safety.

What types of structures can benefit from carbon fiber structural reinforcement?

A wide range of structures can benefit from carbon fiber structural reinforcement, including commercial and residential buildings, bridges, tunnels, water treatment facilities, and historical monuments. This reinforcement technique is particularly valuable for structures showing signs of wear and tear, such as corrosion, cracking, or other forms of deterioration. Additionally, carbon fiber reinforcement is ideal for structures requiring an upgrade in load-bearing capacity or those located in seismic zones needing enhanced earthquake resistance. Its versatility and effectiveness make it a suitable solution for both preventative maintenance and emergency repairs across various construction sectors.

Can carbon fiber reinforcement be applied to both new and existing structures?

Yes, carbon fiber reinforcement can be applied to both new and existing structures. For new constructions, integrating carbon fiber structural reinforcement during the design phase can optimize the structure’s performance, reduce material costs, and enhance longevity. In existing structures, carbon fiber reinforcement is an effective method for restoring and improving structural integrity without the need for extensive demolition or reconstruction. Its application can address specific areas of concern, such as weakened beams, columns, or slabs, providing targeted reinforcement that extends the service life of the structure.

What are the main advantages of using carbon fiber for structural reinforcement?

The main advantages of using carbon fiber for structural reinforcement include its high strength-to-weight ratio, corrosion resistance, ease of application, and minimal thickness addition to the structure. Carbon fiber composites do not add significant weight to the structure, making them ideal for applications where maintaining the original dimensions or aesthetics is crucial. Additionally, their resistance to environmental factors, such as moisture and chemicals, ensures a long-lasting reinforcement solution. The speed and ease of installation, coupled with the ability to tailor the reinforcement to specific structural needs, make carbon fiber an attractive choice for modern construction challenges.

How is carbon fiber reinforcement applied to a structure?

Carbon fiber reinforcement is typically applied to a structure through the use of carbon fiber sheets or fabrics that are saturated with a resin system. The surface of the structure is first prepared to ensure proper adhesion, often involving cleaning and roughening. The carbon fiber material is then cut to size, impregnated with resin, and carefully bonded to the structure’s surface. In some cases, additional layers may be applied to achieve the desired level of reinforcement. The resin is allowed to cure, forming a strong bond that integrates the carbon fiber reinforcement with the structure. This method provides an effective, non-intrusive means of increasing the strength and durability of the structure.

Can carbon fiber structural reinforcement be used in seismic retrofitting?

Carbon fiber structural reinforcement is an excellent option for seismic retrofitting, offering an effective way to enhance the earthquake resistance of buildings and infrastructure. Its application can significantly improve the ductility and energy absorption capacity of structures, allowing them to withstand the dynamic loads and deformations associated with seismic events. Carbon fiber reinforcement can be strategically placed to strengthen critical areas, such as columns, beams, and joints, ensuring that the structure has the resilience needed to protect against earthquake-induced damage.

How does carbon fiber reinforcement compare to traditional reinforcement methods?

Compared to traditional reinforcement methods, such as steel reinforcement, carbon fiber reinforcement offers several advantages, including superior strength-to-weight ratio, corrosion resistance, and ease of installation. Unlike steel, carbon fiber does not corrode, eliminating the need for maintenance related to rust and extending the lifespan of the reinforced structure. Carbon fiber can be applied with minimal disruption to existing operations, making it ideal for retrofitting projects. While the initial cost may be higher than some traditional methods, the long-term benefits and durability provided by carbon fiber often result in a more cost-effective solution over the structure’s lifecycle.

What are the long-term benefits of using carbon fiber for structural reinforcement?

The long-term benefits of using carbon fiber for structural reinforcement are substantial and multifaceted, making it a preferred choice for modern construction and restoration projects. Key benefits include enhanced durability and lifespan of structures, as carbon fiber’s resistance to environmental stressors like corrosion, moisture, and temperature fluctuations significantly reduces the need for frequent repairs and maintenance. Additionally, the superior strength-to-weight ratio of carbon fiber ensures that structures can withstand increased loads and stresses without compromising their integrity or functionality. This reinforcement method also offers improved seismic performance, protecting structures in earthquake-prone areas by increasing their flexibility and energy absorption capabilities. Ultimately, the use of carbon fiber structural reinforcement leads to safer, more reliable, and longer-lasting buildings and infrastructure, providing peace of mind and cost savings over the structure’s lifetime.

What maintenance is required for structures reinforced with carbon fiber?

Structures reinforced with carbon fiber require minimal maintenance compared to those reinforced with traditional materials such as steel. The inherent properties of carbon fiber, including its resistance to corrosion, moisture, and chemical exposure, contribute to its low maintenance requirements. Periodic inspections are recommended to ensure the integrity of the reinforcement and to check for any signs of damage or wear, especially in critical load-bearing areas and points of attachment. In the rare event that damage is detected, repairs can often be performed without the need for complete replacement, further emphasizing the cost-effectiveness of carbon fiber as a reinforcement solution. Overall, the maintenance of carbon fiber-reinforced structures is straightforward and cost-efficient, emphasizing the material’s suitability for long-term structural applications.

Can carbon fiber reinforcement be customized for specific structural needs?

Yes, carbon fiber reinforcement can be highly customized to meet specific structural needs, making it an exceptionally versatile solution for a wide range of applications. The customization can include varying the orientation, thickness, and type of carbon fiber materials used, allowing engineers to tailor the reinforcement to address specific stress points, loading conditions, and architectural requirements. Additionally, carbon fiber systems can be designed to conform to complex shapes and surfaces, ensuring optimal performance and integration with the existing structure. This ability to customize the reinforcement not only enhances the structural integrity and performance of the building or infrastructure but also ensures that aesthetic considerations and historical preservation requirements are met. The adaptability of carbon fiber reinforcement systems allows for innovative and effective solutions to challenging engineering problems, further demonstrating their value in contemporary construction and restoration projects.