GRC Machines

Power Sprays GRC 125

Ürünü İncele

Power Sprays GRC 125 BT

Ürünü İncele

GRC250S Combination Mixer

Ürünü İncele

Power Sprays 3 Liquid Material Dosing Systems

Ürünü İncele

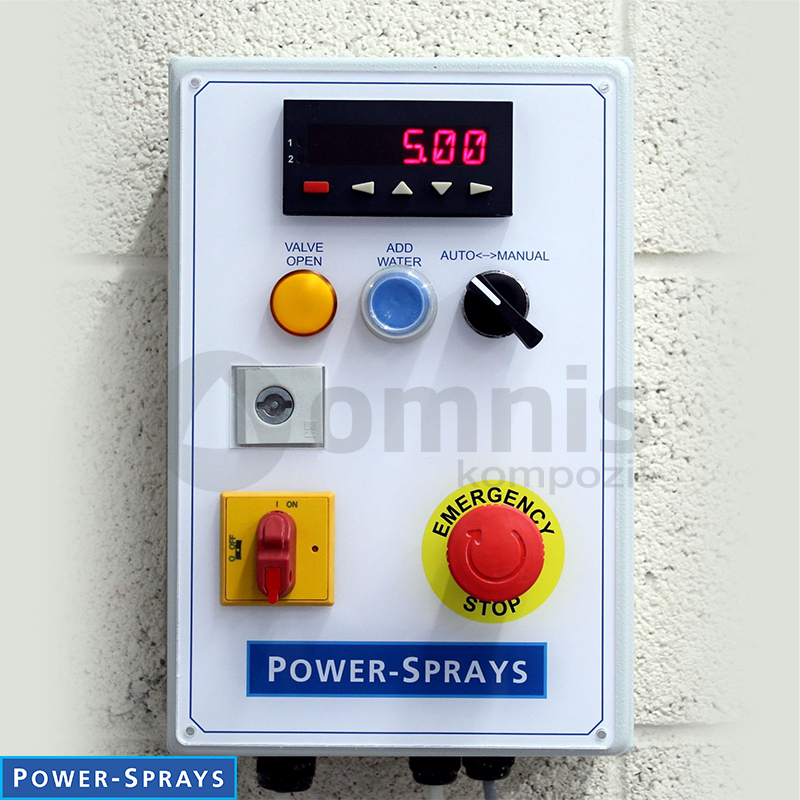

Digital Water Meter

Ürünü İncele

Power Sprays Spray Guns

Ürünü İncele

WAAPS 3000 Liquid Material Dosing Systems

Ürünü İncele

Power Sprays MK3

Ürünü İncele

Power Sprays Light Mist Gun

Ürünü İncele

Power Sprays MK5A

Ürünü İncele

Power Sprays PS 38B

Ürünü İncele

Power Sprays PS 38i

Ürünü İncele

Power Sprays PS 9000i

Ürünü İncele

Power Sprays PS 10000i

Ürünü İnceleWhat is GRC?

GRC consists of high-strength, alkali-resistant glass fibers embedded in a concrete matrix. The fibers act as the main load-bearing component, while the surrounding matrix holds them in place and transfers the load between the fibers. Both fibers and matrix have the ability to retain their physical and chemical properties while combining their properties to form a high-performance composite.

This material is typically produced in thin sections by machine spraying a mixture of enriched ordinary Portland cement and glass fiber aggregate dispersed throughout. These fibers are used for a similar purpose to reinforced concrete steel rebar, but are not susceptible to corrosion.

It can be applied in the same way as natural stone. Glass fiber reinforced concrete panels can also be used as a cladding system because they are lightweight. This panel is 80% lighter than precast steel reinforced concrete cladding. Thanks to this feature, it is easier to install and provides economic cost advantage. Ribbed or sandwich-shaped panels carry many important features with them. It is resistant to fire and weather conditions and has sound insulation properties. For this reason, it is presented as a material mostly used in building projects.

GRC Properties

This material, called glass fiber reinforced concrete, has many features. Its mixture includes fine aggregate, water, chemical additives and alkali-resistant glass fiber. In general, the properties of this concrete are as follows:

After the mixture is ready, it is applied by spraying method.

Since it is resistant to bending, impact and bending, it is used in the construction of earthquake-resistant structures.

As it has a light structure, it eliminates the weight volume in the building.

It offers a safe and long-lasting use with its durable structure.

Since it has a very thin structure, it can take the desired shape. This feature brings great practicality to both designers and workers. Since it takes the desired shape, aesthetic and creative designs can be put forward by giving all kinds of shapes in design areas. For workers, it offers a fast, easy and practical application.

Since it offers long life, it ensures that the structures can be used for years without deformation.

It takes its place among modern building applications by saving time and energy.

It is generally used on exterior facades. But it can also be used to create amorphous surfaces on interior facades.

Since it consists of fireproof material, it offers the opportunity to create a fire-resistant structure.

Since the fiber used in its content is a natural product, it shows that it is an environmentally friendly application.

It is a good decoration and facade cladding material.

How is GRC Made?

Making glass fiber reinforced concrete consists of a specific process. Two different methods are generally used in the production of glass fiber reinforced concrete. In this process, “spraying” or “pre-mixing” methods are used. This superior material is produced by reinforcing a concrete matrix with strong glass fiber fibers. Also known as GFRC, this building material is in great demand in various applications.

In general, spraying method is preferred for large products such as building facade cladding panels, while pre-mix method is preferred for small products.

GRC Usage Areas

GRC is popular today with many uses. In rapidly developing and growing cities, the aesthetic appearance of buildings is as important as their robustness. Earthquake, one of the major natural disaster threats, has a devastating effect if buildings are not durable. The application of this material also comes into play at this time to strengthen the structures. Glass fiber reinforced concrete offers aesthetic solutions as well as functional. Therefore, in this respect, it also gives aesthetic appearances to the areas where it is used. The areas of use of this concrete can be briefly summarized as follows:

Housing

Business center

Shopping center

Hotel

Historical buildings

Permanent mold applications

Exterior and interior facade applications

Architectural applications

Irrigation canals

Bridges

City furniture