Fasteners and Sealants

Spiral Infusion Hose No:4

Ürünü İncele

Infusion Hose 10×12 mm

Ürünü İncele

Infusion Resin T Inlet Connector

Ürünü İncele

Valved Valve

Ürünü İncele

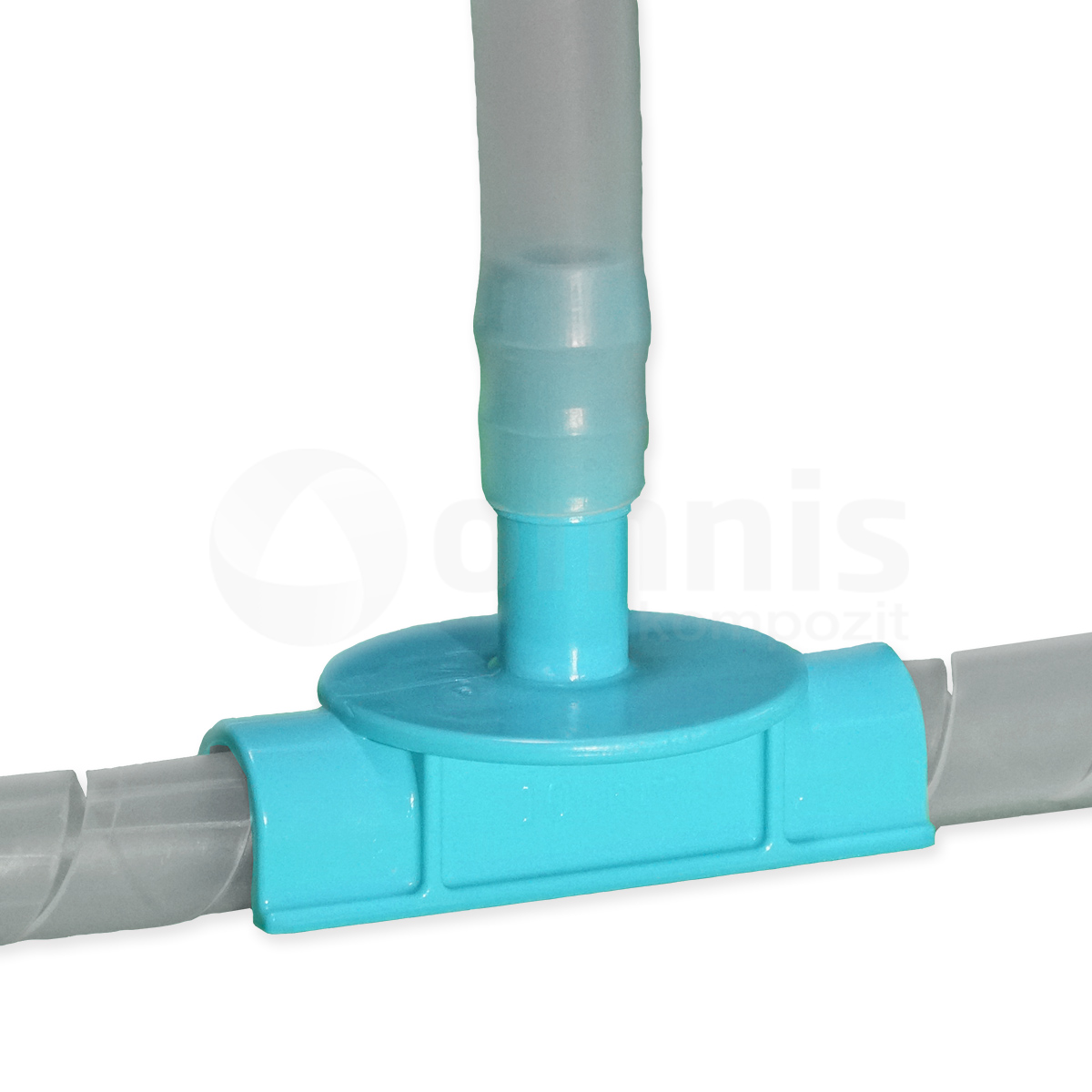

T-Connection

Ürünü İncele

Vacuum Sealing Pastes

Ürünü İnceleWhat are Connection Elements?

Fasteners are important components used in vacuum infusion methods. Fasteners are materials used to connect two or more parts. These materials, which are used to hold the parts together, are usually made of metal or plastic.

Designed in different shapes and sizes, they can be used in various application areas. The main purpose of these elements is to ensure that the joined parts remain stable and aligned. The structures, tools or machines in which it is used become more durable and useful. Omnis Composite offers the following products as fasteners:

T-Connection: The T-connection product has an internal diameter of 10 mm and is compatible with pipes. It is designed to connect resin and air channels to increase efficiency and control in vacuum infusion processes.

Valve: This product has an inner diameter of 10 mm and is suitable for 10 mm pipes. Furthermore, thanks to the valve, the resin or air passage is controlled through the lines.

Infusion Resin T Inlet Connector: Type T10, specially suitable for pipes with an inner diameter of 10 mm. It has a special design and is used together with the spiral resin hose as a resin entry point into the vacuum environment.

Since they are used in various areas, it is necessary to make the right choice among these elements. These products are preferred in industrial sectors as they ensure successful completion of projects and longevity of the products used. It is therefore important to find out where and for what purpose it is used before making a choice.

Where are Fasteners Used?

Fasteners are materials used in specific and general applications. Each one has a unique design but similar functions. Their use is therefore generally similar. The areas where these elements are used are as follows:

Joining of pipe or hose lines: One of the uses of these elements is the joining of pipe or hose lines and wave separation. With this usage area, it is generally preferred in applications such as hydraulic systems, gas distribution, fluid transfer.

Providing fluid and gas control: Since these elements are mechanical materials, they are used in various industrial fields. It is preferred for fluid routing in pipelines, water and gas distribution systems, petrochemical and power plants.

Composite material production: Some fastener products used in the manufacture of composite materials are preferred for bonding processes. It ensures that resin infusion in this area is carried out correctly.

In general, it is also possible to talk about the sectoral usage areas of the elements used for these applications. These elements, which enable different structures to be connected to each other, are generally used in the electronics, construction, machinery and equipment, automotive, furniture, aerospace and defense sectors. These elements, which aim for structural robustness, are preferred because they offer a safe and long-lasting use.

What is Sealing Paste?

Sealing compounds are a material used in various fields of application. It acts as an airtight seal between the vacuum bag and the surrounding mold. Also known as a sealing tape made of synthetic rubber. The sealants can be used in room and medium temperature applications. Sealing paste has various properties. The properties of this material, whose main task is sealing and airtightness, are as follows:

It has excellent adhesion.

High performance delivers a sense of solidity.

Easy cleaning and long shelf life.

Low cost.

It is resistant to moisture.

It is waterproof and has a structure that prevents mold growth.

It is easy to use.

It is more durable than normal adhesive putties.

In general, these are the highlights of the sealing compound. Omnis Composite produces different products in this category. The sealing paste products offered with Omnis Composite quality and their features are as follows:

Spiral Infusion Hose No:4: Spiral infusion hose is used in vacuum infusion applications. Its main function is to ensure that on the inside of the vacuum bag, the resin that passes through the suction line and enters the bag is in the form of a flow channel.

Infusion Hose 10×12 mm: Infusion hose is used in vacuum infusion applications as channels for the flow of resin and air.

Infusion Block Connector: It stands out with its special design and serves as the resin entry point into the vacuum environment with the spinal resin hose.

In Which Areas Is Sealing Putty Used?

Sealants are used in different applications and industries. Sealants that prevent the formation of cracks can be used primarily in the home or workplace. Sealing compounds are considered one of the most important building materials for bathrooms and kitchens as they ensure the sealing of the joints between the plates.

It can also provide insulation for cracks in walls, ceilings or floors. Due to its moisture resistant structure, it is used to fill the gaps in window and door frames. On the other hand, it is possible to use it in bathroom equipment assembly applications due to its waterproof and mold inhibiting properties.

Provides good cold and hot flow in PVC exterior claddings. It is also useful for filling the outlet of heating pipes and boiler headers. Therefore, it can be said that sealing paste is mostly used in the construction sector.