Epoxy Resins

Epoxy resin is a thermosetting polymer known for its strong adhesive properties, high mechanical strength, and durability. It is composed of two parts: the resin and the hardener, which, when mixed together, undergo a chemical reaction that results in a rigid, solid material. Epoxy is celebrated for its excellent chemical resistance, superior adhesion to a wide range of materials, and its ability to form a strong, moisture-resistant bond. These characteristics make it an ideal choice for a variety of applications, from high-performance composites to protective coatings and adhesives in the construction, automotive, and aerospace industries.

How is epoxy resin used in composite materials?

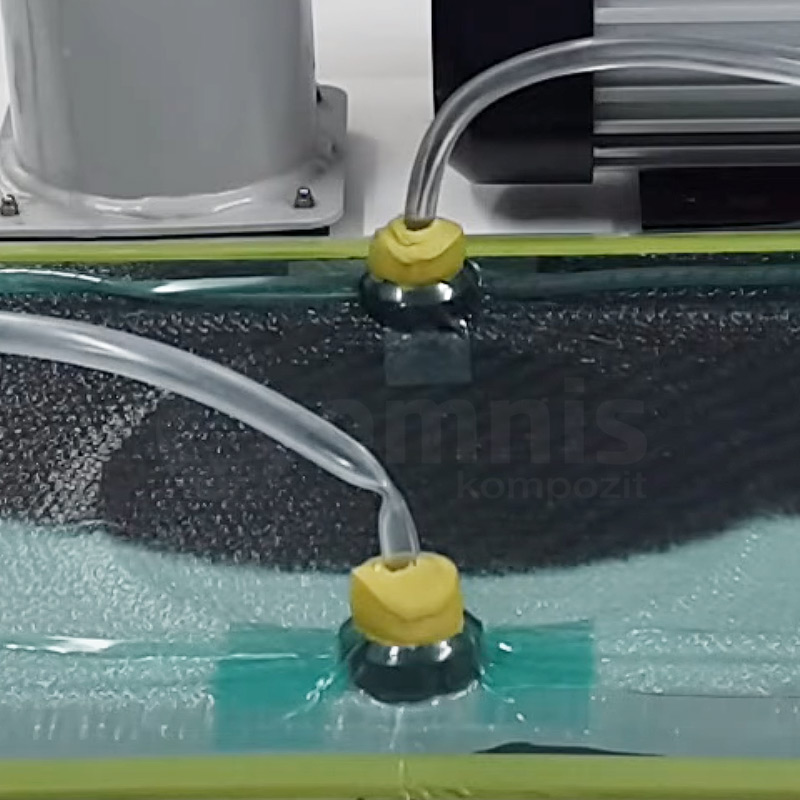

Epoxy resin is used in composite materials as a matrix that binds reinforcement fibers together, such as glass or carbon fiber, to enhance their mechanical properties and durability. Its excellent adhesive qualities ensure a strong bond between the fibers, distributing stress across the composite material and improving its overall strength and stiffness. The resin’s low shrinkage upon curing and its ability to cure at room temperature or with heat make it versatile for manufacturing processes like hand lay-up, vacuum bagging, and resin infusion. These properties make epoxy a preferred choice for high-performance composites in demanding applications.

What are the main advantages of using epoxy resin?

The main advantages of using epoxy resin include its superior mechanical properties, excellent chemical and heat resistance, and strong adhesion capabilities. It offers higher strength and stiffness compared to many other types of resins, making it ideal for load-bearing applications. Its resistance to chemicals and moisture makes it suitable for harsh environments, while its thermal stability allows it to maintain performance at higher temperatures. Additionally, epoxy resin’s excellent adhesion to a wide range of materials ensures durable bonds in composite manufacturing, repair, and coating applications, contributing to the longevity and reliability of the final products.

How do epoxy resins compare to polyester and vinylester resins?

Epoxy resins offer superior mechanical properties, chemical resistance, and durability compared to polyester and vinylester resins. While polyester resin is more cost-effective and faster curing, it has lower strength and is less resistant to chemicals and moisture than the epoxy one. Vinylester resin provides a middle ground with better chemical resistance and mechanical properties than polyester but still falls short of epoxy’s performance. Epoxy resin’s excellent adhesion, low shrinkage, and superior strength make it the preferred choice for high-performance applications requiring long-term durability, such as in aerospace, marine, and automotive industries.

In what applications is epoxy resin most commonly used?

Epoxy resin is most commonly used in applications requiring high strength, durability, and chemical resistance. These include aerospace and automotive components, marine construction, such as boat hulls and decks, wind turbine blades, sports equipment, and high-performance composites. The resin is also widely used in the electronics industry for encapsulating and protecting circuit boards, in the construction industry for structural repairs and as a protective coating for floors and other surfaces, and in arts and crafts for creating jewelry and decorative items.

Can epoxy resin be used with both glass and carbon fiber reinforcements?

Yes, epoxy resin can be used with both glass and carbon fiber reinforcements, providing excellent adhesion and compatibility with these materials. Its ability to form strong, durable bonds with reinforcement fibers enhances the mechanical properties of the composite, such as strength, stiffness, and impact resistance. The resin’s versatility makes it suitable for a wide range of composite applications, from high-performance aerospace and automotive components to recreational sports equipment and marine structures, where the benefits of glass and carbon fiber reinforcements are maximized.

What are the curing characteristics of epoxy resin?

The curing characteristics of epoxy resin involve a chemical reaction between the resin and hardener that transforms the liquid mixture into a solid, thermoset polymer. This process can occur at room temperature or can be accelerated with heat. Resin has a variable pot life and cure time, which can be adjusted by the choice of hardener and the addition of accelerators or inhibitors. The curing process results in minimal shrinkage, ensuring dimensional stability of the final product. Proper curing is essential for achieving the desired mechanical properties and chemical resistance of the epoxy composite.

How does epoxy resin perform in terms of strength and durability?

Epoxy resin performs exceptionally well in terms of strength and durability. It exhibits high tensile strength, compressive strength, and flexural strength, making it capable of withstanding significant loads and stresses. Its excellent adhesion to a variety of substrates contributes to its durability, ensuring long-lasting bonds that resist peeling, cracking, and moisture ingress. Its chemical resistance protects against corrosion and degradation in harsh environments, while its thermal stability maintains performance under elevated temperatures. These properties make epoxy resin ideal for demanding applications where long-term reliability is critical.

Can epoxy resin be used in high-temperature applications?

They can be used in high-temperature applications, although its performance is dependent on the specific formulation and the operating temperature range. Standard epoxy resins typically withstand continuous exposure to temperatures up to about 120-150°C (248-302°F). For applications requiring higher temperature resistance, special high-temperature epoxy formulations are available that can maintain their mechanical properties and dimensional stability at elevated temperatures. These high-temperature epoxies are used in aerospace, automotive, and industrial applications where thermal resistance is crucial.

What safety precautions should be taken when working with epoxy resin?

When working with epoxy resin, it is important to take safety precautions to protect against skin irritation, allergic reactions, and inhalation of fumes. Wear protective gloves, long sleeves, and safety goggles to prevent skin contact. Use a respirator or ensure adequate ventilation in the work area to avoid inhaling vapors, especially in enclosed spaces. Follow the manufacturer’s safety instructions and refer to the safety data sheets (SDS) for specific handling guidelines. Clean any spills immediately and wash hands thoroughly after handling the product to minimize exposure.

How do environmental conditions affect the curing of epoxy resin?

Environmental conditions, such as temperature and humidity, significantly affect the curing of epoxy resin. Higher temperatures generally accelerate the curing process, while lower temperatures can slow it down or even prevent complete curing. High humidity levels can introduce moisture into the resin, potentially affecting the cure and final properties of the epoxy. It is important to cure the product under controlled conditions, following the manufacturer’s recommendations, to ensure optimal performance and mechanical properties of the cured material.

What are the storage and handling guidelines for epoxy resin?

The storage and handling guidelines for epoxy resin include keeping it in a cool, dry place away from direct sunlight and extreme temperatures. Resin and hardener components should be stored in tightly sealed containers to prevent contamination and moisture absorption. Ensure that the storage area is well-ventilated and that personal protective equipment is used when handling the resin to avoid exposure to chemicals. Follow the manufacturer’s instructions for shelf life to ensure the quality of the resin before use. Proper storage and handling practices are essential for maintaining the performance and safety of epoxy resin.

How does the cost of epoxy resin compare to other types of resins?

The cost is generally higher than that of polyester and vinylester resins, reflecting its superior mechanical properties, durability, and chemical resistance. Despite its higher initial cost, the resin’s performance advantages and long-term durability can make it a cost-effective choice for applications requiring high strength, environmental resistance, and longevity. The decision to use the product over other types of resins should consider the specific requirements of the application and the overall value provided by the material in terms of performance and lifespan.