- Technical Bulletin

- 18 Sep 2023

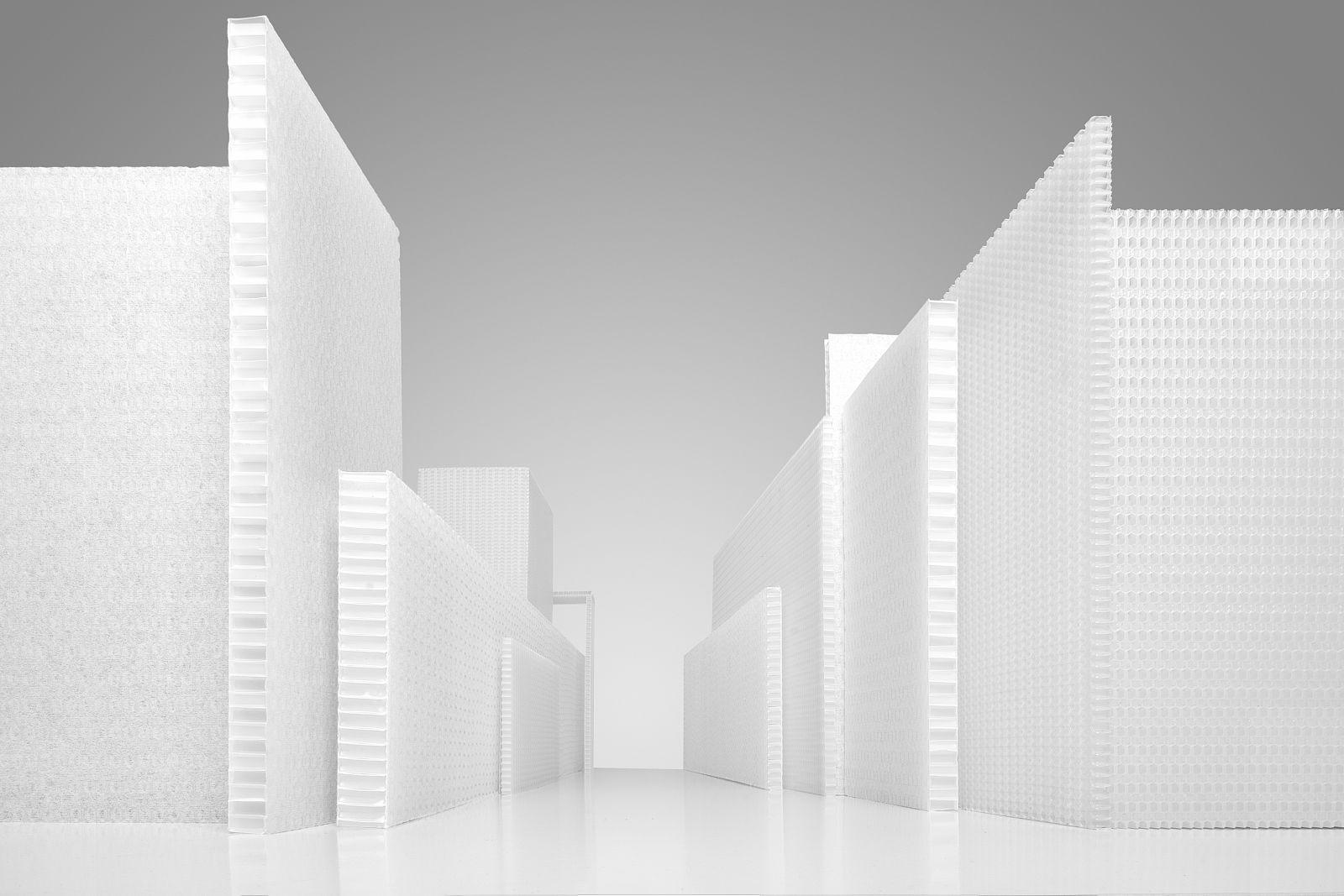

ThermHex Definition and Application Areas

Thermhex plays a leading role in the production of lightweight sandwich panels thanks to the special structure it has developed. This innovative product offers significant advantages over alternative core materials, providing up to 85% lighter weight. PP Honeycomb Plates are designed for composite applications with a German patented seamless and seamless production system. The product shows high mechanical resistance and provides superior protection against chemical substances. It is also resistant to moisture and performs effectively against weather conditions. It is also environmentally advantageous as it is a fully recyclable product. Read on to find out more about this advantageous and qualified product.

What is ThermHex?

Thermhex is a special and innovative core material used in lightweight sandwich panels. This product is lighter than chipboard because it is made of polypropylene. The main features of Thermex PP Honeycomb Plates are as follows.

- Easily machinable, the surface is coated with a polyester surface fleece, which ensures very good compatibility with composite laminates and superior surface performance.

- Since it is produced with polypropylene material, it has superior strength and low density.

- It is an environmentally friendly industrial product because it is 100% recyclable. It can therefore be used in projects that embrace sustainable production.

- Resistant against moisture and corrosion. Provides good heat and moisture insulation.

- It is a product that meets the requirements of various sectors as it has wide areas of use.

In general, these properties help to produce many products used in industry and daily life. Its high strength, light weight and longevity make it the preferred choice for some applications. Therefore, it stands out with its innovative and efficient solutions for many sectors.

Technical Information About ThermHex

After describing Thermhex in general, it is worth mentioning some of its technical features. This product, which is obtained from polypropylene components through a special process, is used in various applications thanks to its technical properties. The technical features of this product are:

- It is produced in 3 different options with a density of 60, 80 and 120 kg/m3 as standard.

- Based on the standard size, it is produced in 2500mm x 1200mm sheet size. However, it is also offered in different sizes in line with the demands in special application areas.

- It has a thermal transmittance of 0.065 W/mK.

- Normally non-flammable. (class B2 DIN 4102-1 and class D according to EU classification)

- The fire resistance of sandwich panels can be increased according to the choice of material used. Thus a higher fire rating can be achieved.

- The length is + 10 /- 1 mm and the width is + 2 /- 1 mm. Core thickness is +/- 0.3 mm. Size variability is + /- 0.2°.

- This product has high chemical resistance and is resistant to many acid, water, base and salt solutions.

- It has UV resistance in case normal coating material is used.

- Suitable for fiber spray-up and hand lay-up applications.

Its effective performance in application areas is due to the fact that it has these features. Therefore, its technical features should be taken into account in areas where this product will be preferred. Thus, a more accurate, high-performance and efficient product will be used in the application areas.

ThermHex PP Honeycomb Plate Usage

* Pasting

It is important to use Thermhex plates with the right adhesives. Since the honeycomb core material has a special surface, full performance is obtained when used with high quality and highly effective adhesives. It can be used with adhesives developed for polyester, vinylester, epoxy, acrylic or methacrylate-based composite applications, depending on the area to be bonded and the type of use. When selecting the adhesive, it should be checked that it is suitable for all component materials of the sandwich plate.

* Lamination

This material can be laminated with different production methods. Laminated panels offer customized solutions for some industry areas. When laminating, hand lay-up and fiber spraying methods can be used as various production methods. Thermhex products can be laminated with epoxy, polyester, vinylester and polyurethane resins. Although the purpose of each resin is binding and bonding, the resins have different technical properties, so the end products can have a variety of uses and functions.

* Spraying

Fiber spraying is ideal for the production of composite parts, which often have a large surface area. In simple terms, this method involves chopping the fibers and spraying them with resin onto the mold surface under pressure. Graco spray systems are generally recommended for this production system.

* Shaping

Thermex PP Honeycomb Plates can be shaped by heat. In this way, it may be possible to pre-form the core structure so that it fits better in the mold before molding. In addition to heat forming, low thickness honeycomb sheets between 3.5 – 10 mm can also be formed by vacuum or pressure at room temperature. During the forming process, the appearance and mechanical properties of the surface of the panels can be changed.

* Cut

Thermex plates can be easily cut with almost all conventional cutting methods. These cutting systems include CNC, laser, blade and rotary blades, band saw and water jet. Each cutting system has different shaping, cutting performance and utilization. Therefore, the right cutting system should be selected according to the application areas.

* Closing the Plate Ends

Depending on the application and need, the ends can be closed using different methods. The edges of the plate can be closed at an angle between 15-30 degrees by forming with heat and pressure by ironing. The edges of Thermhex plates can also be covered with bay window edgebanding tapes used to cover the edges of chipboard and MDF plates. Edge bands are applied by gluing with a suitable adhesive. A profile can be used as a third method of edge closure. The profile geometry is chosen to fit inside the plate and glued along the plate using a suitable adhesive. Aluminum, iron or ctp profiles can be used.

ThermHex Application Areas

Among the sectors and main application areas where Thermhex, PP Honeycomb Core Plates are used are the following:

Building and construction: In the building industry, this product is used in exterior cladding, partition panels and wall panels. Due to its lightness and ease of processing, it also creates solutions in interior architecture, furniture and decoration.

Industrial areas: The number of industrial products, systems and solutions produced with Thermhex plates, which are used in different areas such as wind turbines, floating piers, water jet cutting, packaging and box production, is constantly increasing.

Transportation and Logistics: Thermhex is mainly used in transportation vehicles such as trucks, caravans, ambulances, refrigerated and refrigerated trailers and buses. The relative lightness of the sandwich structure compared to the strength it provides positively affects the fuel efficiency of the vehicles.

Marine industry: Used in boat construction, this material is useful for deck reinforcement, load-bearing walls, furniture, hull and interior trim applications. Thanks to its durability, it ensures that marine transportation vehicles are safe and long-lasting. One of the reasons for its use in this sector is its resistance to water, acid and salt solutions.

As a result, Thermhex is a material used in various application projects. Multi-purpose and very useful, this product offers solutions that work in various sectors. For this reason, it has a wide range of uses from the construction sector to the maritime sector.