- Blog

- 31 Oct 2025

Interlaminar Shear Strength Test: What It Is and How It Works

Understanding how composite materials behave under different forces is critical in industries like aerospace, automotive, and construction. One of the key mechanical properties tested in composites is their resistance to internal layer separation, also known as interlaminar shear strength. The interlaminar shear strength test helps engineers measure how strong the bond is between layers in a laminated material. This test is essential during the processing of composite materials to ensure structural reliability, especially where layered construction is involved. While many mechanical tests such as tensile testing or non-destructive testing focus on surface or overall structural performance, the interlaminar shear strength test gives specific insights into what happens between the layers of composite structures.

What Is Interlaminar Shear?

Interlaminar shear refers to the force that causes layers within a composite material to slide over each other. In layered composites—like carbon fiber reinforced plastics, these layers are bonded together with a matrix resin. When stress is applied, especially in bending or torsion, the internal layers may start to separate if the bonding is weak. This failure between layers is called delamination, and it’s a major concern in many high-performance applications.

Understanding interlaminar shear is crucial because it directly affects the durability and performance of the composite part. For example, in aircraft wings or automotive panels, delamination can lead to sudden material failure. The interlaminar shear strength test helps engineers detect weaknesses in the bond between layers before the part is put into real-world use. This way, manufacturers can ensure higher quality and reduce the risk of product failure.

While composite fatigue testing looks at how materials perform under repeated stress over time, interlaminar shear testing focuses on the bond strength between the layers under a single or short-term load. Together, these tests provide a more complete picture of a material’s reliability.

Overview of the Interlaminar Shear Strength Test

The interlaminar shear strength test is designed to evaluate how much shear force a composite material can handle before the layers start to separate. This test is especially useful for laminated composites, where multiple layers are stacked and bonded together. The goal is to simulate real-world stresses that occur inside the material—stresses that might not be visible on the surface.

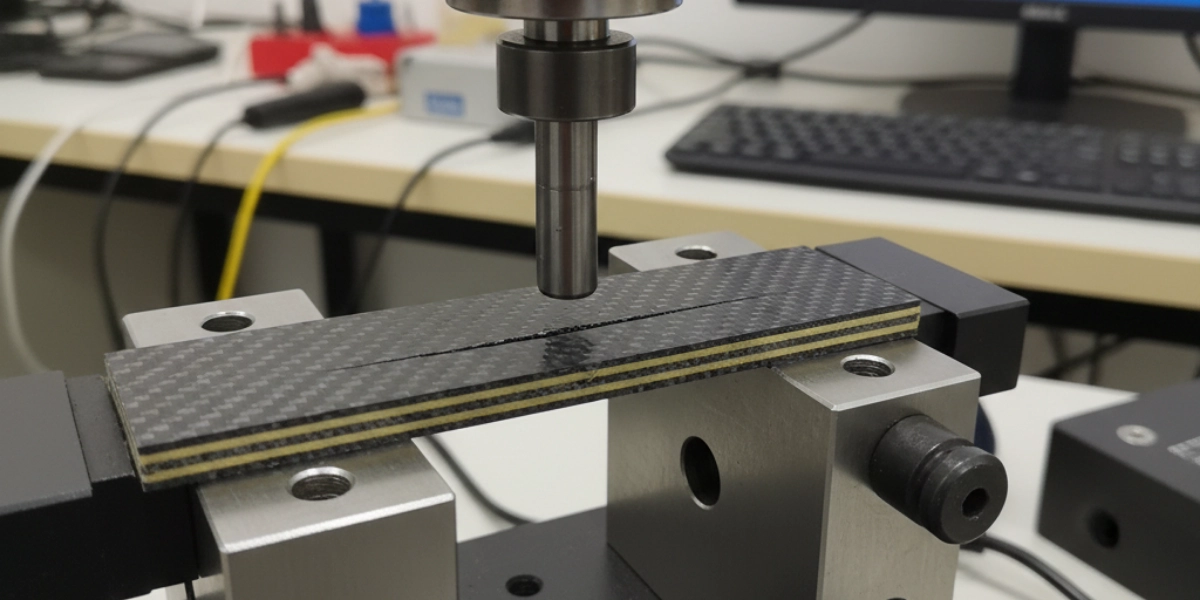

Typically, a small rectangular sample of the composite is used. This sample is subjected to a loading method that forces shear between the layers. The most common way to do this is by applying a compressive force in a short beam configuration. As the load increases, the internal layers experience shear stress until failure occurs. The point at which the material breaks or shows signs of internal cracking is recorded as its interlaminar shear strength.

This test plays a key role in the processing of composite materials, especially during quality control or material selection. It allows manufacturers and engineers to compare different materials, bonding methods, or curing processes. Unlike other tests such as tensile testing, which measure force in a single direction, interlaminar shear testing provides unique insight into the internal cohesion of layered composites.

Standard Testing Methods and Equipment

To ensure reliable and repeatable results, the interlaminar shear strength test follows internationally recognized testing standards. These standards define how the test should be performed, which type of sample should be used, and what equipment is required. The two most commonly used standards are ASTM D2344 and ISO 14130. Each method is designed to simulate short-beam loading and focuses on evaluating shear failure between the composite layers.

ASTM D2344 – Short Beam Shear Test

ASTM D2344 is one of the most widely used methods for interlaminar shear strength test in fiber-reinforced composites. This method involves placing a short composite specimen on a three-point bending fixture. The span-to-thickness ratio is intentionally low (usually around 4:1) to induce shear failure rather than bending failure.

Here’s how it works:

- The sample is loaded in a testing machine using a three-point setup.

- Force is applied from the top while the sample rests on two support points.

- Because of the short span, the internal layers of the sample are forced to slide against each other, creating shear stress.

- The maximum load the sample can take before failing gives the interlaminar shear strength value.

This method is especially useful in production settings due to its simplicity and speed. However, it’s considered a non-destructive testing alternative only when used to monitor changes over time with subcritical loads. Otherwise, it is generally destructive.

ISO 14130 – Shear Testing in Plastics and Composites

ISO 14130 is the international equivalent of ASTM D2344, but with more detailed specifications. It also uses short-beam shear testing to evaluate laminated plastics and fiber-reinforced composites. The main differences lie in the sample dimensions, precision of the test setup, and some procedural aspects.

This standard is often preferred in European and global markets and is especially relevant for cross-border quality assurance in composite manufacturing.

Advantages of ISO 14130 include:

- Higher consistency in international testing environments.

- More detailed instructions for preparing and conditioning samples.

- Optional parameters for testing composites under various environmental conditions (e.g., humidity, temperature).

Both standards aim to measure the same property, and in most cases, either can be used depending on regulatory requirements or customer expectations.

Required Test Fixtures and Machine Setup

For both ASTM D2344 and ISO 14130, a universal testing machine with a three-point bending fixture is essential. The setup includes:

- Two lower support points spaced to create the required short span.

- One loading nose that applies force vertically on the midpoint of the sample.

- Adjustable span-to-thickness ratios (usually 4:1) to ensure shear rather than bending failure.

- Fixtures must be aligned precisely to avoid introducing bending moments or uneven stress.

It’s also important to calibrate the machine properly and ensure uniform loading speed. Sample dimensions must match the standard’s guidelines, and surface defects should be avoided to maintain accuracy.

Test Procedure Step by Step

Conducting an interlaminar shear strength test requires careful preparation and a controlled testing environment to ensure accurate, repeatable results. Below is a simplified, step-by-step overview of the standard procedure used in both ASTM D2344 and ISO 14130 methods.

1. Sample Preparation

- Cut composite specimens to the correct size (typically 20–30 mm in length, 6 mm in width, and 2–4 mm in thickness, depending on the standard).

- Make sure edges are smooth and free from cracks or delaminations.

- Condition the samples, if required, by exposing them to a controlled environment (e.g., humidity or temperature) for a specified time.

2. Machine Setup

- Mount the three-point bending fixture on a calibrated universal testing machine.

- Adjust the support span according to the specified span-to-thickness ratio (usually 4:1).

- Set the loading speed (commonly around 1 mm/min) to ensure a controlled application of force.

3. Positioning the Sample

- Place the specimen on the supports so that it is centered under the loading nose.

- Ensure that the sample is level and correctly aligned to prevent uneven loading or bending stresses.

4. Running the Test

- Start the test and apply force through the loading nose.

- Monitor the load continuously. The goal is to induce shear stress between the internal layers of the composite, not flexural failure.

- Stop the test once the maximum load is reached or visible signs of delamination occur.

5. Calculating Results

- Use the maximum force recorded during the test to calculate the interlaminar shear strength using the formula provided in the relevant standard.

- Inspect the sample to confirm that the failure occurred due to shear and not other factors like flexural cracking.

This procedure provides reliable data on the internal bond strength between layers of composite materials. Compared to methods like tensile testing, which assess material strength in one direction, this test gives a more focused view of layered bonding performance—making it essential in structural composite design.

Factors Affecting Test Accuracy and Results

The interlaminar shear strength test is a powerful tool, but its accuracy depends on several critical factors. If not properly controlled, these variables can lead to inconsistent or misleading results, making it difficult to compare materials or identify real weaknesses.

1. Specimen Quality and Preparation

Poorly prepared samples can significantly affect test results. Common issues include:

- Surface cracks or edge defects, which may cause premature failure.

- Inconsistent thickness, leading to uneven loading.

- Incorrect fiber orientation or layup, which changes how the material responds to shear.

Proper cutting tools, careful handling, and strict preparation guidelines help reduce these risks.

2. Fixture Alignment and Span Ratio

Misaligned test fixtures or incorrect span-to-thickness ratios can shift the failure mode from shear to bending. If the span is too long, the sample may fail in flexure, not in shear—invalidating the results. A ratio of around 4:1 is optimal for ensuring shear failure.

3. Loading Speed and Machine Calibration

If the load is applied too quickly or the testing machine is not calibrated correctly, the results may vary between tests. Most standards call for a slow and steady loading rate to ensure consistent shear stress buildup. Regular calibration of the test machine is also essential to maintain accuracy.

4. Environmental Conditions

Temperature and humidity can impact the adhesive bond between composite layers. For example, high humidity might weaken the resin matrix, leading to lower shear strength. Testing under controlled environmental conditions ensures better repeatability.

5. Material Fatigue and History

If the sample has previously been used in composite fatigue testing, even at low loads, micro-damage could already exist within the layers. This would affect the shear strength measurement, as the material has already been weakened. Only fresh or properly documented samples should be tested.

Overall, the interlaminar shear strength test is a vital method for evaluating the internal bonding performance of composite materials. By focusing on the shear stress between layers, this test provides essential insights that other methods—like tensile testing or surface-level non-destructive testing—may overlook. Following recognized standards such as ASTM D2344 and ISO 14130 ensures consistency and reliability, while proper setup and sample preparation are key to accurate results.

For manufacturers and engineers involved in the processing of composite materials, understanding and applying this test correctly can lead to stronger products, fewer failures, and greater confidence in final applications. Whether used in aerospace, automotive, or construction, interlaminar shear testing remains a trusted tool for quality control and performance verification in modern composite design.