- Blog

- 30 Apr 2025

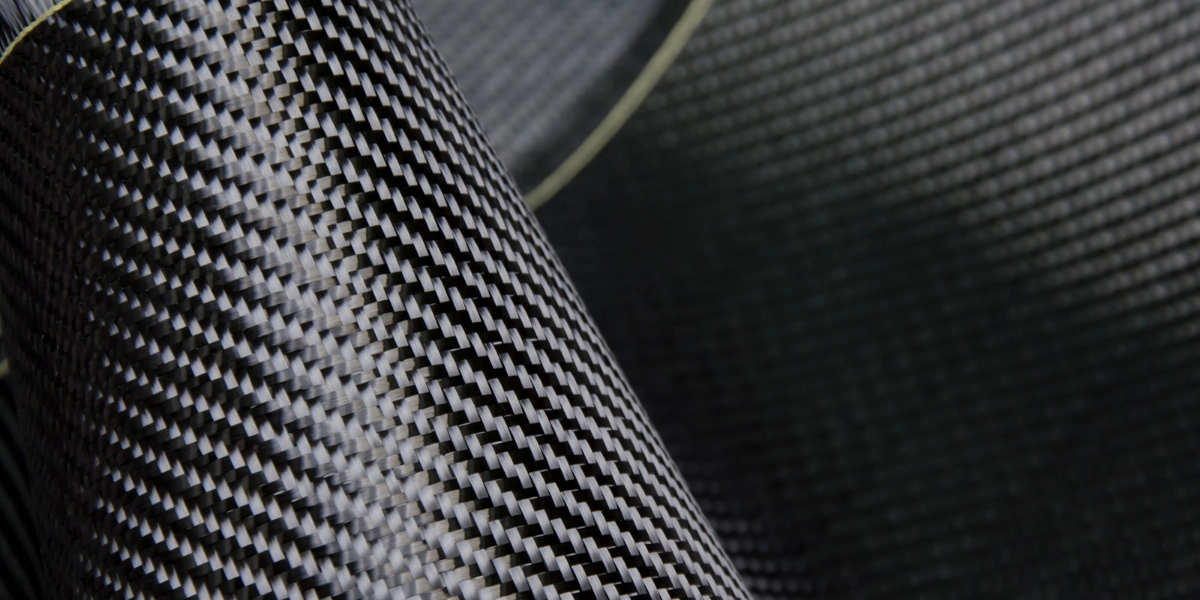

The Future of Materials: Hybrid Composites

As industries continue to demand stronger, lighter, and more sustainable materials, hybrid composites, also known as mixed-fiber composites, are stepping into the spotlight. These advanced materials combine two or more types of fibers or matrices to achieve better performance than traditional single-component materials. From aerospace to automotive and even healthcare, mixed-fiber composites are reshaping how we build, protect, and innovate. Their ability to offer flexibility, durability, and eco-friendliness makes them a key player in the future of material science. In this article, we’ll explore what hybrid composites are, where they are used, and why they are gaining attention across so many sectors.

What Are Hybrid Composites?

Hybrid composites are materials made by combining two or more different types of fibers or reinforcements within a single matrix. The goal is simple: bring together the best features of each material to create a final product that performs better than any single material could on its own. For example, a hybrid composite might blend the strength of carbon fiber with the flexibility of natural fiber to create a structure that is both tough and lightweight.

Unlike traditional composites that use only one type of fiber, mixed-fiber composites are all about balance. You can pair synthetic fibers like aramid fiber—known for its high strength and impact resistance—with environmentally friendly options like basalt fiber, which offers good thermal stability and is naturally fire-resistant. These combinations allow manufacturers to fine-tune the final product’s behavior, depending on what’s needed—be it durability, flexibility, weight reduction, or cost-efficiency.

The matrix that holds the fibers together can be made of different materials too, including thermoplastic composites, which are especially valued for their recyclability and ease of processing. This flexibility in both fiber and matrix choice opens the door to countless design possibilities.

In short, mixed-fiber composites are not just about mixing materials—they’re about mixing performance, sustainability, and innovation in a single, smart solution.

Applications of Hybrid Composites in Different Industries

Hybrid composites are quickly becoming essential in a wide range of industries thanks to their smart material design. Their ability to deliver strength, lightness, and resistance to wear makes them ideal for applications where traditional materials fall short.

In the aerospace industry, mixed-fiber composites are used in aircraft structures to reduce weight while maintaining high strength. This helps improve fuel efficiency and overall performance. In automotive manufacturing, these materials are used in car bodies, panels, and interior parts to make vehicles lighter and safer without compromising durability.

The construction sector also benefits. Mixed-fiber composites are used in bridge components, panels, and reinforcement systems. Their corrosion resistance and long lifespan reduce maintenance needs and costs over time. For sports and leisure, these materials appear in bicycles, helmets, skis, and racquets—offering excellent strength-to-weight ratios that boost both safety and performance.

In healthcare, mixed-fiber composites are used for prosthetics, dental materials, and medical devices. For instance, combining flexible and stiff fibers allows for the creation of more comfortable and functional prosthetic limbs. This is especially useful in health tourism, where patients often seek advanced, long-lasting solutions that also look natural.

Whether it’s high-speed trains or wind turbines, mixed-fiber composites adapt well to specific demands, helping engineers solve complex challenges with tailor-made material combinations.

Advantages of Hybrid Composites Over Traditional Materials

When compared to traditional materials like metal, wood, or single-fiber composites, mixed-fiber composites offer a range of unique advantages that make them a smart choice for modern applications.

One of the biggest benefits is customization. By combining different fibers—each with its own strength, weight, or resistance level—manufacturers can design materials that meet very specific performance needs. For example, using aramid fiber for impact resistance and basalt fiber for heat tolerance creates a material that performs well in demanding environments, such as aerospace or defense.

Lightweight strength is another key advantage. Hybrid composites can be much lighter than metals, yet just as strong—or even stronger. This helps reduce energy use in transportation and improves ease of handling in manufacturing.

Durability also sets mixed-fiber composites apart. These materials resist corrosion, fatigue, and wear much better than many conventional materials. As a result, they last longer, require less maintenance, and reduce overall replacement costs.

In addition, the use of natural fiber in hybrid designs supports sustainability goals. It reduces environmental impact while still offering the mechanical properties needed for performance.

Overall, mixed-fiber composites provide a powerful mix of strength, efficiency, and flexibility. This makes them ideal for industries looking to innovate without compromising quality or sustainability.

The Role of Hybrid Composites in Future Innovations

As technology continues to evolve, mixed-fiber composites are expected to play a central role in the development of next-generation products. Their ability to combine performance with sustainability makes them an ideal solution for industries focused on innovation and environmental responsibility.

In future transportation, mixed-fiber composites will likely shape the next wave of electric vehicles, drones, and high-speed trains. These materials can reduce overall weight without compromising safety—helping vehicles travel farther on less energy. They also offer design flexibility, making it easier to develop sleek, aerodynamic shapes that traditional materials can’t support.

Smart infrastructure is another area where mixed-fiber composites will make an impact. Bridges, buildings, and urban structures will increasingly use advanced materials that self-monitor for damage, adapt to stress, or resist extreme weather. Thanks to their corrosion resistance and tailored strength, mixed-fiber composites will support longer-lasting, more intelligent structures.

In medical technology, lightweight and adaptable materials are essential. Hybrid composites will enable the creation of more comfortable prosthetics, advanced implants, and even bio-compatible devices that work more naturally with the human body.

Looking forward, research is already exploring ways to integrate mixed-fiber composites with sensors, AI systems, and eco-friendly production methods. As new combinations of fibers and matrices emerge, these materials will help solve complex challenges across industries—making them key to building a smarter, more sustainable future.

Hybrid composites are more than just a trend—they represent a shift toward smarter, stronger, and more sustainable materials. By blending the best properties of different fibers, including innovations like aramid fiber, basalt fiber, and natural fiber, these advanced materials are opening new possibilities across industries. From transportation to healthcare, mixed-fiber composites are helping shape a future where performance, efficiency, and environmental care go hand in hand. As demand for high-performing materials continues to grow, mixed-fiber composites will remain at the heart of innovation.