Building and Construction

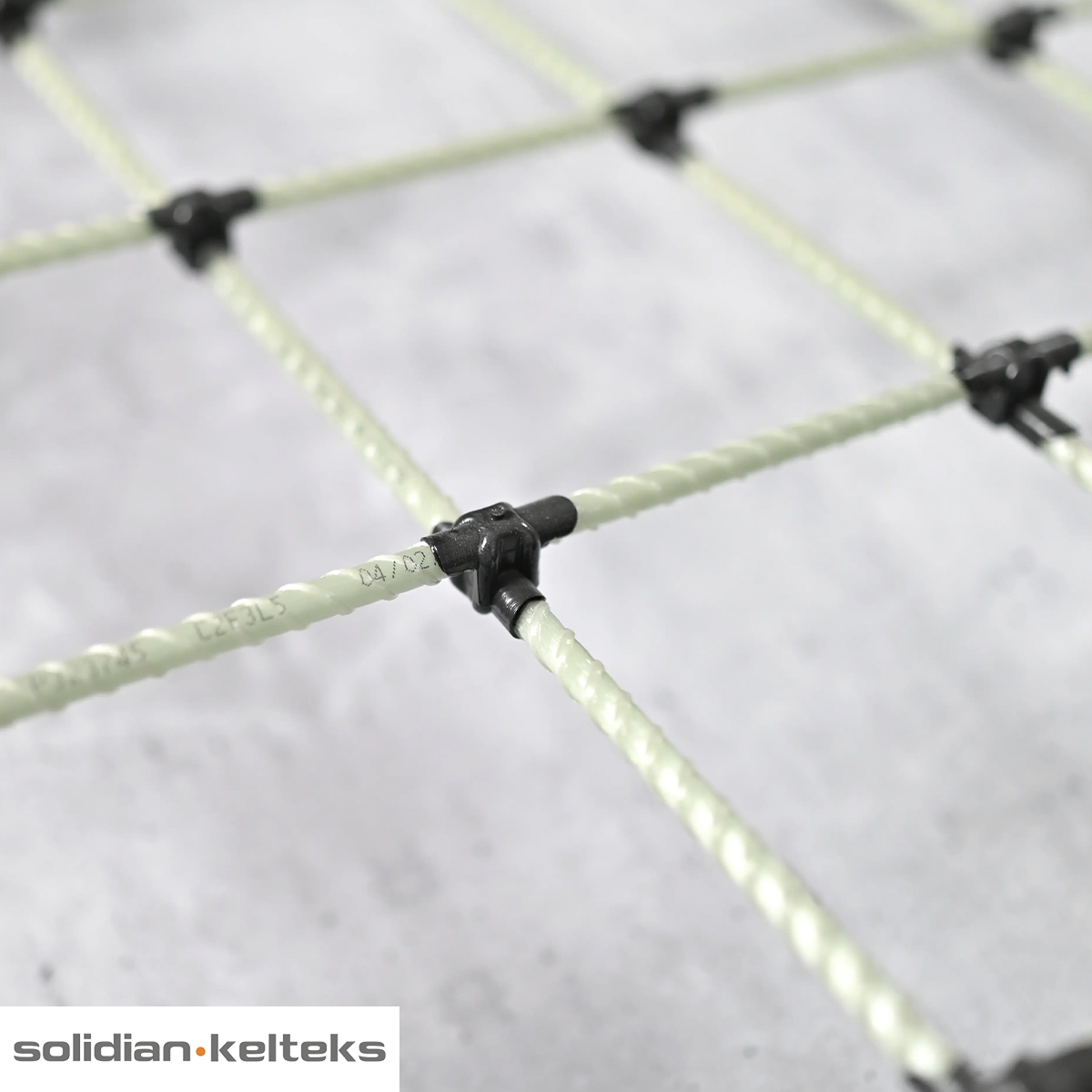

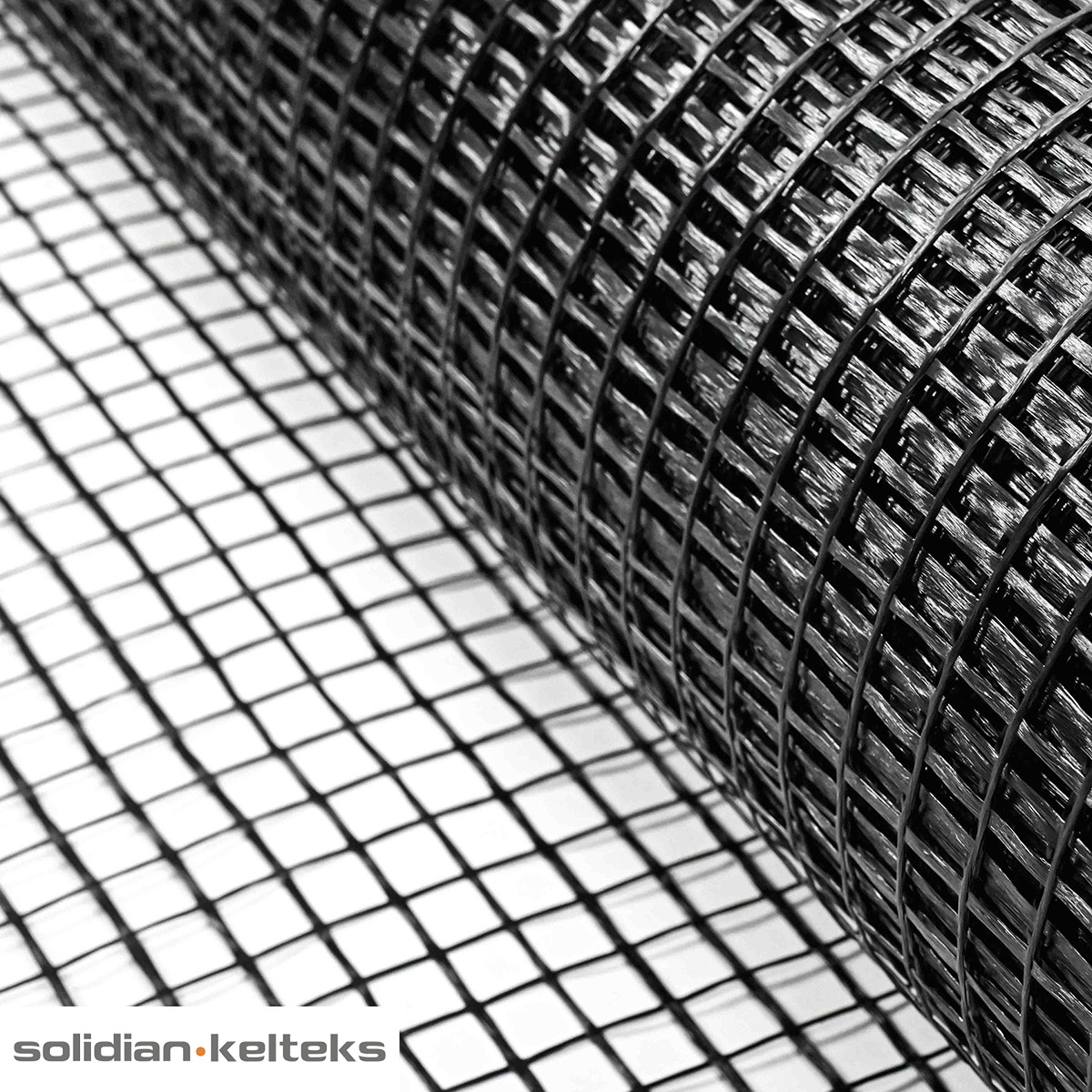

Composite materials are revolutionizing the composite in the construction industry with their unique properties and versatile applications. Composites, which are a combination of two or more distinct substances, offer superior strength, durability, and design flexibility. Commonly used composite materials in construction include fiberglass, carbon fiber, and reinforced plastics.

What sets composites apart in the construction industry is their high strength-to-weight ratio, corrosion resistance, and ability to be molded into complex shapes. These properties make composites ideal for a wide range of construction applications, from bridges and buildings to facades and infrastructure.

Moreover, composite materials in construction can be tailored to specific requirements, offering a wide range of mechanical, thermal, and electrical properties. Their composition can be adjusted to achieve desired characteristics, such as increased stiffness or improved fire resistance, crucial for the composite in the construction sector.

Historical Evolution of Composites in Construction

The use of composite materials in construction can be traced back centuries, with evidence of their early use found in ancient civilizations such as Egypt and Greece. However, it wasn’t until more recent history that composites gained significant prominence in the construction industry, marking a pivotal role for composite in construction throughout the ages.

During World War II, fiberglass composites emerged as a breakthrough material for constructing lightweight aircraft. This marked a turning point in the adoption of composite materials in construction, significantly impacting the construction industry. The success of fiberglass composites in construction during this era underscored the potential of composite materials in construction settings, paving the way for broader acceptance and application.

In the mid-20th century, the construction industry began to recognize the benefits of using composite materials in construction for various applications, including bridges, tanks, and pipes. This awareness led to further advancements in manufacturing techniques and material science, resulting in the development of high-performance composites with superior mechanical properties. This period marked a significant advancement in the use of composite in construction, reflecting a growing appreciation for the unique advantages that these materials could bring to the construction industry.Perhaps one of the most significant advancements in composites was the introduction of carbon fiber composites in the late 20th century. These lightweight and durable materials revolutionized the construction industry, leading to the construction of structures that were previously unimaginable. The role of composite in construction became even more pivotal with this innovation.

Today, composites are extensively utilized in a wide range of construction projects, including bridges, buildings, facades, and infrastructure. The continuous evolution and widespread adoption of composite materials in construction demonstrate their instrumental role in advancing the field and meeting the demands of modern construction.

Key Advantages of Using Composites in Construction Projects

Composite materials offer several key advantages that make them highly beneficial for construction applications. Two primary advantages of composites in construction are their exceptional durability and longevity, as well as their impressive weight-to-strength ratio.

Durability and Longevity of Composite Materials

Composite materials are renowned for their durability and long service life, making them ideal for construction projects that require long-lasting and reliable structures. Unlike traditional materials such as steel or wood, composites do not rot, warp, or degrade over time. They are highly resistant to corrosion, chemical reactions, and weathering, resulting in reduced maintenance requirements. This resilience makes composite materials in construction particularly valuable for ensuring long-term durability and sustainability. The utilization of composite in construction materials in this context underlines their importance in creating enduring structures.

Composites in construction are capable of withstanding harsh environmental conditions, including extreme temperatures and UV radiation, without compromising their structural integrity. Their non-porous nature prevents moisture absorption, minimizing the risk of damage caused by water or chemicals. Additionally, composites are designed to withstand external impacts and resist fatigue, reducing the need for frequent repairs or replacements. The application of composite in construction materials thereby significantly enhances the resilience and longevity of infrastructure, marine structures, and industrial facilities where long-term performance and reliability are critical.

Another significant advantage of composites in construction is their outstanding weight-to-strength ratio. Composite materials offer high strength and stiffness while remaining lightweight. In many cases, composites outperform traditional materials such as steel or concrete in terms of strength. The application of composites in construction projects leverages this benefit, allowing for lighter structures and potential cost savings in foundations and transportation. Incorporating composite in construction materials in such projects showcases their superiority in strength and efficiency.

Due to these exceptional durability characteristics, composites in construction are widely used in construction projects such as infrastructure, marine structures, and industrial facilities where long-term performance and reliability are critical. The inherent durability and low maintenance requirements of composite materials in construction significantly contribute to their preferred status in these applications. The adoption of composite in construction materials in these areas emphasizes their pivotal role in modern construction practices..

Weight-to-Strength Ratio

Another significant advantage of composites in construction is their outstanding weight-to-strength ratio. Composite materials offer high strength and stiffness while remaining lightweight. In many cases, composites outperform traditional materials such as steel or concrete in terms of strength. This aspect of composite in construction material technology highlights its significance in modern construction practices.

The low weight of composites allows for the construction of lighter structures, leading to cost savings in foundations and transportation. The reduced dead load of composite structures in construction not only minimizes material consumption but also contributes to improved energy efficiency and sustainability. Incorporating composite in construction activities can significantly influence the overall efficiency and cost-effectiveness of building projects.

Furthermore, composites’ high strength properties ensure the structural integrity of buildings and infrastructure, ensuring safety and performance. By optimizing the weight-to-strength ratio, composites in construction enable efficient designs and reduced material consumption, aligning with sustainability goals and supporting environmentally conscious construction practices. The role of composite in construction thus extends to enhancing safety and promoting green building initiatives.

In applications where weight reduction is critical, such as aerospace structures, lightweight bridges, and portable buildings, composite materials in construction offer significant advantages over traditional construction materials. The utilization of composite in construction sectors that require lightweight yet strong materials showcases the versatile benefits of composites in addressing diverse engineering challenges.iverse engineering challenges.

Comparative Analysis: Composites vs. Traditional Building Materials

When comparing composites to traditional building materials, it is essential to consider both cost-efficiency over time and the environmental impact and sustainability considerations. While composites may have a higher upfront cost than traditional materials, their long-term cost-efficiency often outweighs the initial investment.

Cost-Efficiency Over Time

One of the key advantages of composites in construction is their durability and low maintenance requirements. Unlike traditional materials, composites in construction do not require frequent repairs or replacements, resulting in reduced lifecycle costs. Additionally, composites are lightweight, which can lead to cost savings in transportation and installation, especially for large-scale construction projects.

In contrast, traditional materials like steel or concrete may require additional reinforcements, increasing construction time and expenses. Composites in construction, on the other hand, can be molded into the desired shape, reducing labor and material costs. The design flexibility of composites in construction also allows for efficient use of materials, minimizing waste and optimizing resource utilization, leading to cost reductions and improved sustainability.

Furthermore, composite materials in construction can contribute to long-term cost savings through improved energy efficiency and insulation properties. The lightweight nature of composites in construction helps reduce heating or cooling requirements in buildings, resulting in reduced energy consumption. These cost-saving measures can significantly impact the overall operational costs of a construction project.

Environmental Impact and Sustainability Considerations

One of the key advantages of composites in construction is their durability and low maintenance requirements. Unlike traditional materials, composites in construction do not require frequent repairs or replacements, resulting in reduced lifecycle costs. Additionally, composites are lightweight, which can lead to cost savings in transportation and installation, especially for large-scale construction projects.

In contrast, traditional materials like steel or concrete may require additional reinforcements, increasing construction time and expenses. Composites in construction, on the other hand, can be molded into the desired shape, reducing labor and material costs. The design flexibility of composites in construction also allows for efficient use of materials, minimizing waste and optimizing resource utilization, leading to cost reductions and improved sustainability.

Furthermore, composite materials in construction can contribute to long-term cost savings through improved energy efficiency and insulation properties. The lightweight nature of composites in construction helps reduce heating or cooling requirements in buildings, resulting in reduced energy consumption. These cost-saving measures can significantly impact the overall operational costs of a construction project.

Installation Techniques and Best Practices for Composite Materials

Proper installation techniques are essential to ensure the successful integration of composite materials in construction projects. The installation process for composites in construction may vary depending on the specific material and application but generally involves proper surface preparation, adhesive application, and curing.

Composite panels and components should be carefully handled during transportation and installation to prevent damage or delamination. In addition to proper handling, sealing, and weatherproofing techniques are critical to maintain the performance and durability of composite materials in construction environments.

To ensure structural integrity and maximize the benefits of the material, it is important to follow manufacturer guidelines and industry best practices when installing composites in construction projects. This includes using approved adhesives, using the correct curing time and temperature, and following any specific instructions for surface preparation.

Regular inspection and maintenance of installed composite materials in construction are necessary to identify any potential issues or damage and address them promptly. This includes checking for signs of delamination, cracking, or wear, and addressing any identified issues in a timely manner.

By following proper installation techniques and best practices, construction projects can benefit from the unique properties of composite materials, such as their high strength-to-weight ratio, corrosion resistance, and design flexibility, resulting in durable and sustainable structures. This makes the role of composites in construction increasingly significant for modern infrastructure.

Emerging Trends in Composite Materials for Building and Construction

The construction industry is experiencing a constant evolution in composite material technology, paving the way for exciting new trends and applications. Ongoing research and development efforts are focused on enhancing the performance, durability, and sustainability of composite materials in construction.

Advancements in Composite Material Technology

Advancements in composite manufacturing processes, such as automated production techniques and 3D printing, have revolutionized the construction industry. These advancements enable faster and more efficient construction methods, reducing time and cost while maintaining high-quality standards.

New composite formulations and additives are being developed to improve specific properties, such as fire resistance, thermal conductivity, and acoustic insulation. By tailoring the composition of composites, manufacturers can achieve desired characteristics and meet the requirements of various construction applications.

Incorporating nanotechnology and smart materials into composites offers even more possibilities. These advancements lead to enhanced functionality, self-healing capabilities, and improved energy efficiency. Composite materials are becoming smarter, providing sustainable solutions for building and construction projects.

The use of bio-based resins and recycled reinforcements is another emerging trend in composite materials. This promotes the circular economy and reduces reliance on fossil fuels. By incorporating sustainable materials, the construction industry can contribute to a more environmentally friendly future.

The Role of Composites in Green Building Certification

Composite materials play a significant role in achieving green building certifications, such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method). The sustainable characteristics of composites, including durability, lightweight, and energy efficiency, align with the principles of green building design and construction.

By incorporating composites into sustainable building projects, construction professionals can earn points and credits in various categories, such as materials and resources, indoor environmental quality, and innovation. The environmental benefits of composites, such as reduced energy consumption, waste reduction, and recyclability, support the goals and requirements of green building certification programs.

Design teams and construction professionals are increasingly recognizing the crucial role that composites play in achieving sustainable and environmentally responsible buildings. The use of composites not only supports sustainability goals but also drives further innovation and adoption in the construction industry.

Maintenance and Repair: Extending the Life of Composite Constructions

Ensuring the longevity and optimal performance of composite structures requires regular inspection and maintenance protocols. It is essential to conduct routine inspections to identify any signs of damage, delamination, or degradation in the composite components. Visual assessments can be conducted to detect visible issues, while non-destructive testing techniques like ultrasonic testing or thermography can uncover hidden defects or structural problems.

Maintenance practices for composite structures include cleaning, surface treatment, and the application of protective coatings. Proper cleaning and surface treatment can prevent degradation caused by UV exposure or chemical reactions. Following manufacturer recommendations and industry standards for maintenance procedures and frequency is crucial. Qualified professionals should conduct routine inspections to promptly address any potential areas of concern, ultimately extending the life of composite constructions.

If damage or deterioration occurs, various repair techniques can be employed to restore the integrity and functionality of composite constructions. Patching, laminate replacement, or resin infusion techniques may be used, depending on the extent and type of damage. It is important to assess the damage properly and consult experts or manufacturers to determine the most suitable repair strategy.

Long-term maintenance strategies for composite constructions involve periodic cleaning, surface protection, and monitoring for any signs of degradation or wear. Regular inspections and preventive maintenance play a key role in identifying potential issues at an early stage, preventing more extensive damage or failure. The effective implementation of repair and maintenance practices can maximize the lifespan of composite constructions, ensuring their continued performance and safety.