Concrete Chemicals and Fillers

Concrete chemicals are specialized formulations designed to modify and enhance the properties of concrete at various stages of its life, from mixing and pouring to curing and long-term maintenance. These additives play a pivotal role in improving the performance, workability, durability, and aesthetic qualities of concrete, making them indispensable in modern construction practices. By selecting the appropriate concrete chemicals for your project, you can achieve superior results, ensuring that your concrete structures are strong, durable, and visually appealing.

GRC Flexible Mold

View Product

Powder Pigment

View Product

Acrylic Polymer

View Product

Powder Polymer

View Product

Silica Sand AFS 30-35

View Product

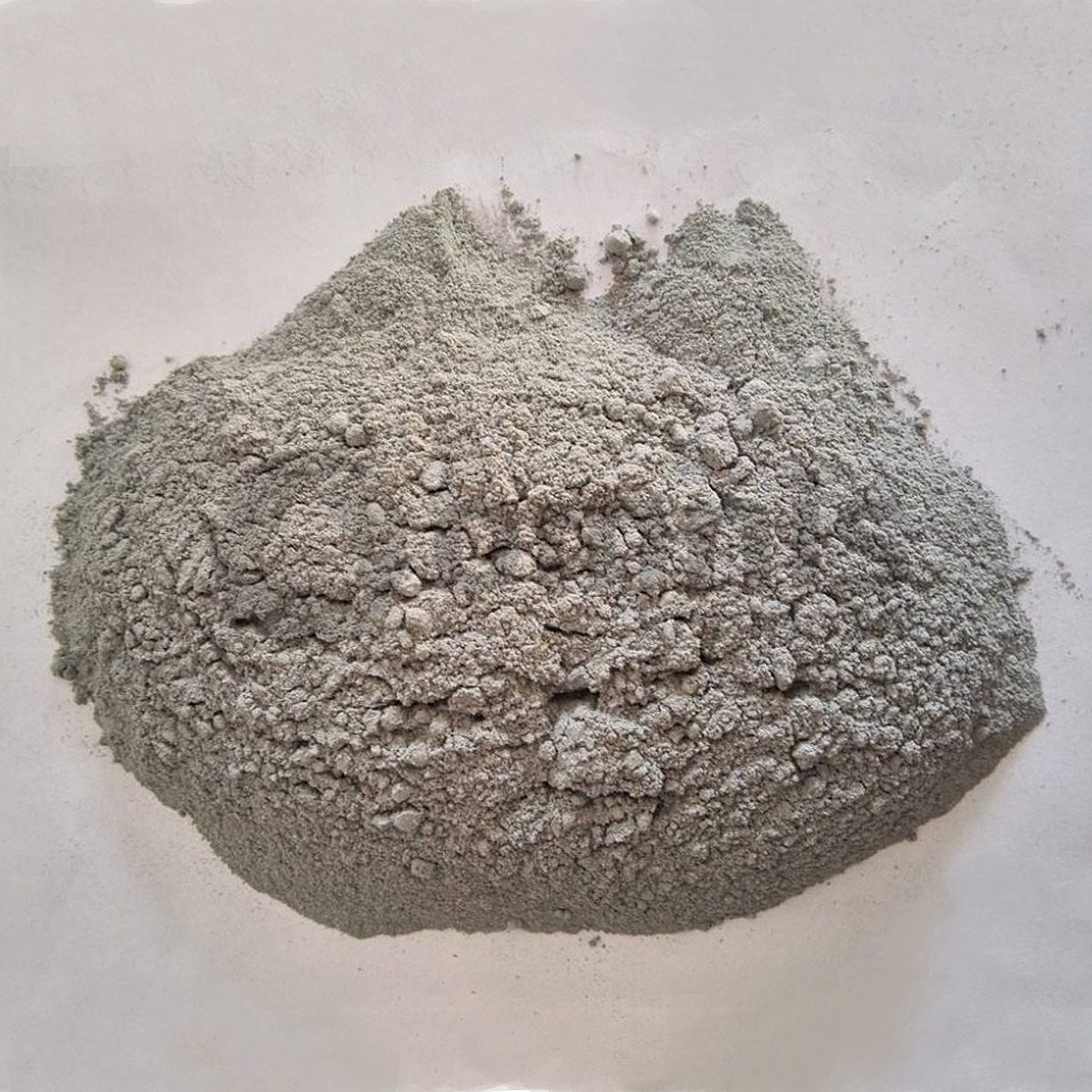

Micro Silica-Silica Ash-Fume

View Product

Mold Release Agent for Concrete Applications

View Product

Concrete Plasticizer

View Product

Stikloporas Expanded Glass

View ProductHow do concrete chemicals enhance the performance of concrete?

Concrete chemicals enhance the performance of concrete by targeting specific needs such as improved workability, accelerated curing times, increased strength, and enhanced durability. They work by interacting with the cementitious materials within the concrete mix, optimizing the hydration process, and modifying the physical properties of the concrete. The result is a concrete mix that is easier to work with, cures more efficiently, and achieves superior strength and durability, significantly extending the life and functionality of concrete structures.

What types of concrete chemicals are commonly used?

Commonly used concrete chemicals include superplasticizers for enhanced workability, accelerators to speed up curing time, retarders to delay setting time in hot weather, water-reducers to decrease water demand, and air-entraining agents to improve freeze-thaw resistance. Each of these additives is specifically designed to address particular challenges in concrete construction, ensuring optimal performance across a wide range of environmental conditions and applications. By carefully selecting and applying these concrete chemicals, constructors can achieve desired outcomes, such as smoother finishes, faster construction timelines, and long-lasting durability.

Can concrete chemicals improve the workability of concrete?

Yes, concrete chemicals can significantly improve the workability of concrete. Superplasticizers, one of the most commonly used types of concrete chemicals, reduce the water content in the concrete mix without compromising its fluidity, making the concrete easier to place, compact, and finish. This improved workability is particularly beneficial in complex forms or intricate designs, ensuring a high-quality finish with less effort and reducing the potential for defects.

How do concrete chemicals affect the curing time of concrete?

Concrete chemicals can be formulated to either accelerate or retard the curing time of concrete. Accelerators are used to speed up the hydration process, allowing concrete to set and gain strength faster, which is especially useful in cold weather or when rapid construction is required. Conversely, retarders slow down the setting time of concrete, providing more time for placing and finishing in hot weather or in large-scale pours. These adjustments in curing time offer flexibility in construction scheduling and ensure the integrity and performance of concrete structures.

Are there concrete chemicals that can increase the strength of concrete?

Yes, there are concrete chemicals designed to increase the strength of concrete. These include various types of admixtures such as silica fume, fly ash, and slag cement, which enhance the concrete’s physical properties and microstructure, resulting in higher compressive and tensile strength. By incorporating these concrete chemicals into the mix, constructors can achieve more robust and resilient structures capable of withstanding greater loads and stresses over time.

How do concrete chemicals contribute to the durability of concrete structures?

Concrete chemicals contribute to the durability of concrete structures by enhancing resistance to environmental stresses, reducing permeability, and improving chemical resistance. Additives such as waterproofing agents and corrosion inhibitors protect concrete from moisture ingress, freeze-thaw cycles, and corrosive elements, significantly extending the lifespan of concrete structures. By improving the concrete’s inherent qualities, these chemicals ensure that structures remain strong, functional, and aesthetically pleasing for decades.

Can concrete chemicals be used in both residential and commercial construction?

Concrete chemicals are versatile and can be used in both residential and commercial construction projects. Their application ranges from simple home renovations to large-scale commercial and infrastructure projects. Depending on the specific requirements of the project, such as strength, durability, or aesthetic appeal, the appropriate concrete chemicals can be selected and applied to achieve the desired outcomes. This versatility makes concrete chemicals a valuable tool in the construction industry, enhancing the quality and performance of concrete across a wide range of applications.

Do concrete chemicals help in reducing water permeability in concrete?

Yes, concrete chemicals such as waterproofing admixtures and pore fillers are specifically designed to reduce water permeability in concrete. These additives modify the concrete’s microstructure, filling in pores and capillaries, and forming a barrier against water ingress. This not only protects the structural integrity of concrete but also prevents damage from freeze-thaw cycles and chemical attacks. By incorporating these concrete chemicals, constructors can ensure more durable and watertight structures, suitable for challenging environmental conditions.

How are concrete chemicals applied to existing concrete structures?

The application of concrete chemicals to existing concrete structures is a critical process aimed at improving or restoring the structure’s properties, such as strength, durability, and impermeability. These chemicals include a wide range of products like sealers, hardeners, waterproofing agents, corrosion inhibitors, and repair mortars. The method of application and the specific product used depend on the intended purpose, the condition of the concrete, and environmental considerations. Here’s a general overview of how these chemicals are applied:

1. Surface Preparation

- Cleaning: The concrete surface must be thoroughly cleaned to remove dirt, grease, oil, existing coatings, or any contaminants that might interfere with the adhesion of the chemical product. Cleaning methods include pressure washing, sandblasting, or chemical cleaning.

- Repairing: Any cracks, voids, or damaged areas should be repaired prior to the application of concrete chemicals. This might involve filling cracks or applying a concrete patching compound.

- Drying: The surface often needs to be dry before the application of certain chemicals, although some products are designed for use on damp concrete.

2. Application Methods

- Brushing or Rolling: For smaller areas or where precision is required, brushes or rollers can be used to apply sealers, coatings, or waterproofing agents. This method ensures a controlled application rate and is suitable for both horizontal and vertical surfaces.

- Spraying: Large areas can be more efficiently covered by spraying. This method requires specialized equipment and is used for a wide range of chemicals, including curing compounds, form release agents, and waterproofing coatings. Uniform coverage is essential to achieve effective results.

- Pouring and Spreading: For some treatments, like certain floor hardeners or densifiers, the chemical is poured onto the surface and then spread evenly with a squeegee or broom.

- Injection: Cracks or voids within the concrete can be filled by injecting epoxy or polyurethane-based fillers under pressure. This method is commonly used for structural repairs or to seal water-bearing cracks.

3. Finishing Touches

- Smoothing and Leveling: After application, some products may require smoothing or leveling to ensure an even coverage and to integrate seamlessly with the existing concrete surface.

- Curing: Certain chemical applications may require a curing period, during which the treated surface should be protected from traffic, water, or other environmental conditions that could affect the chemical’s performance.

4. Safety and Environmental Considerations

- Personal Protective Equipment (PPE): The use of appropriate PPE is crucial to protect workers from chemical exposure during application.

- Ventilation: Adequate ventilation is necessary, especially for indoor applications or when using volatile organic compounds (VOCs).

- Environmental Protection: Measures should be taken to prevent runoff or spills that could harm the environment.

5. Follow Manufacturer’s Instructions

Each product comes with specific instructions from the manufacturer regarding preparation, application, curing times, and safety precautions. These guidelines are tailored to ensure the optimal performance of the product and must be followed closely.

By adhering to these general steps and specific manufacturer instructions, existing concrete structures can be effectively treated with chemical products to extend their lifespan, enhance their appearance, or restore their integrity.

How do concrete chemicals interact with other additives in concrete mixtures?

The interaction of concrete chemicals with other additives in concrete mixtures is complex and varies based on the types of additives and their intended purposes. Concrete chemicals and additives are used to modify the properties of concrete in its fresh or hardened state, including its workability, setting time, strength, durability, and resistance to environmental conditions. These can include admixtures, supplementary cementitious materials (SCMs), fibers, and other specialty chemicals. Understanding the interaction between these components is crucial for achieving the desired concrete performance.