- Technical Bulletin

- 18 Oct 2023

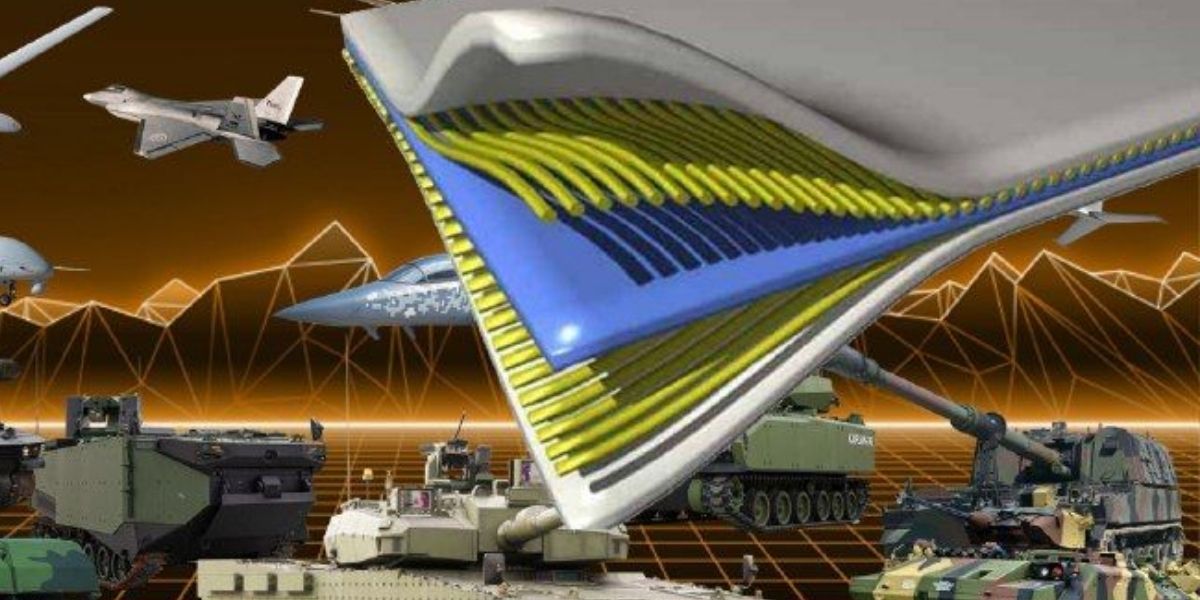

Use of Composite Materials in Defense Industry Increases

Defense industry composite materials are available in many types. In the defense industry, some tools and equipment are needed. Every country responsible for protecting its borders must do so with certain tools and equipment. Manpower is insufficient at a certain point. Especially in the field of national defense, it is important for countries to be equipped against external threats.

In the defense industry created by national capitals, there are products that are widely used in terms of security. Land vehicles, armored vehicles, naval vehicles and UAVs play an important role in this regard. It is widely used in helmets or bulletproof vests or gun bodies, which are among the materials used for the protection of military personnel. Defense industry composite materials stand out with their durability due to their properties. Therefore, it has an important place in the defense industry.

Composite Materials and Importance in Defense Industry

The use of composite materials in the defense industry is widespread. It is worth looking at the properties of these materials first. First of all, composite materials are characterized by their high strength despite their light weight. The fact that they are less harmful to the environment compared to metals makes them suitable for use in the defense industry. It is also very convenient as it requires less maintenance. Defense industry composite materials are important in terms of the following benefits they provide:

- Their high strength/density ratio increases their use in the military field.

- Thanks to their low specific gravity, they offer better cost-effective fuel utilization in vehicles.

- In addition, its lightweight structure facilitates the transportation of military equipment such as armor, helmets and weapons. This provides military personnel with better mobility.

- It is also widely used in transportation vehicles in the military field. Composites play a major role in different applications in aircraft, helicopters and similar aircraft.

- Its use is important in conditions of war and conflict as it increases military capacity and provides protection for military personnel.

- The use of composites in fireproof military tents also provides a safe shelter for military personnel.

- It has been used in many military vehicles and equipment to contribute to the development of the defense industry in today’s conditions. Examples include unmanned aerial vehicles, wing and tail elements of aircraft, and liquid armor.

Composite Materials Used in Defense Industry

When it comes to composite materials in the defense industry, many vehicles and equipment should come to mind. They are part of military equipment and vehicles thanks to their electrical properties, protection against chemical influences and vibration damping. Armor and some vehicles stand out in particular. Below is information on some important military vehicles and equipment where composites are widely used in the military field.

1. Liquid Armor

Defense industry composite materials are used in liquid armored vehicles. Unlike traditional solid armor, liquid armor is in liquid form. However, they have the property of hardening on impact. This type of armor, called “shear stress hardening” material, provides protection by solidifying during many hazards. It is remarkable for its instant solid form against impacts such as bullets, arrows and knives.

2. Armor for Tanks and Aircraft

Composite materials, a type of lightweight material, reduce weight when used in military vehicles. Despite this, the 30 mm thick carbon fiber reinforced airframe provides high strength. It has a body 10% lighter than steel. However, it offers high protection and helps ensure safe transportation for military personnel.

3. Reinforced Thermoplastics

Fiber-reinforced thermoplastics are among the composites commonly used in military transport vehicles. In military transportation vehicles, composites are widely used in parts such as bodywork, roof, bumper and doors. To reduce weight, it is beneficial to use it in railings, body panels, fenders and wheel wells.

Polymer matrix composites, which are among the defense industry composite materials, are used in roof coverings and body parts in military vehicles. Glass fiber polypropylene (PP-GF) is used in battery cases, engine cladding and similar parts.

4. Carbon Fiber Composite

Carbon fiber composite is also included within the scope of defense industry composite materials. This is a material used in parts of military aircraft. This material, which provides high strength, also helps to increase the load capacity. This composite component, which is maintenance-repairable and offers high corrosion resistance, is used in some parts of military and civil aircraft.

5. Composites Used in Ballistic Armor

Kevlar is also among the defense industry composite materials. This material is resistant to burning, melting and flowing. It has a high tensile strength with high flexibility. It is resistant to chemicals as well as providing a high level of resistance to heat. In the military, Kevlar is used in the manufacture of helmets and vests and for vehicle protection.

6. Polymer Concrete Composites

This composite material is being developed for military applications in coastal coastal areas. Natural and synthetic resins were used in its construction. Polymer concrete composites are also used in the construction and repair of helicopter and airplane runways and highways. It increases the mobility of military personnel in coastal and coastal areas as well as desert and high altitude areas.

7. Composite Panel Systems

The composite panel system, which is among the defense industry composite materials, protects soldiers from many dangers. Developed by the Center for Advanced Engineering Wood Composites (University of Maine, USA), this material can be used in US army tents. The material is designed to protect soldiers in temporary headquarters from ballistic attacks.

8. Composite Fuse Relay Box

Among the defense industry composite materials, the composite fuse relay box is made of glass fiber reinforced polyamide. The system, consisting of two boxes, protects the vehicle from short circuits. The centralized control of the entire electronic system is one of its highlights. It has a structure resistant to mechanical stress. Only one screw is needed to attach it to the vehicle. Thanks to its structure with functional parts, it has a snap-on connection and holding system without using any connection. The box in the engine compartment is made of composite fuse relay box, which helps to provide resistance to chemicals.

9. Composite Military Boats

Defense industry composite materials include composite military boats. Made of advanced composite materials, it is also light in weight. It has a corrosion resistance feature that enables maintenance costs to be reduced. It is designed to be used as a military transport boat or patrol boat.

Use of Composite Materials in Military Helicopters

Defense industry composite materials are mostly preferred in military helicopters. Composite applications in military helicopters, which began in the 1970s, aim to reduce helicopter weights. This material, which offers an advantageous opportunity in terms of cost, is still used today.

The EH 101 Merlin was one of the first helicopters to be produced in this material. Using glass and carbon fiber reinforced plastic, this model is resistant to stresses during flight and landing. It is also robust and durable because it is made of composite. Another helicopter model using carbon-epoxy in the front is the NH 90 military transport helicopter. With the use of composites, there is no need for the joints and joints required for metal.

Composite Material Usage Volume in Defense Industry

Defense industry composite materials stand out with their high usage volume. The defense industry is a sector that has developed with technological advances to meet security needs from the past to the present. Composite is a widely used component in a variety of vehicles, tools, equipment and materials. From airplanes to armored vehicles, rockets to missiles and protective elements such as helmets.