- Blog

- 14 Aug 2025

How Tensile Testing Reveals Material Strength

Understanding the strength and flexibility of materials is essential in many industries, especially when it comes to developing strong, reliable composite materials. One of the most trusted methods to measure this is tensile testing—a process that shows how a material behaves under stretching forces. This type of test is especially useful in composite testing, where it helps compare the performance of different substances, including various types of resins in composites. Whether you’re working in dental labs, manufacturing, or materials research, knowing how tensile tests work can help you choose the right materials for better, longer-lasting results.

What is Tensile Testing?

Tensile testing is a method used to check how strong a material is when it is pulled or stretched. In this test, a sample is slowly pulled from both ends until it breaks. This shows how much force the material can handle and how it changes shape before breaking. It’s a simple but powerful way to learn about a material’s strength, flexibility, and performance.

This kind of test is especially important in composite testing, where different materials—like fiber-reinforced plastics or dental composites—need to be compared. For example, by testing various types of resins in composites, we can see which ones are more durable, flexible, or better for specific uses like dental restorations or prosthetics. Tensile testing helps engineers, dentists, and researchers choose the right materials for safe and lasting results.

How Tensile Testing is Performed

Tensile testing may sound technical, but the process is straightforward when broken down. It involves preparing a sample, placing it in a special machine, and pulling it slowly until it breaks. The goal is to measure how the material reacts under tension—how much it stretches, when it starts to deform, and when it finally breaks. Let’s look at the equipment used and the step-by-step process.

Standard Equipment Used in Tensile Testing

To perform a tensile test, a few key tools are needed:

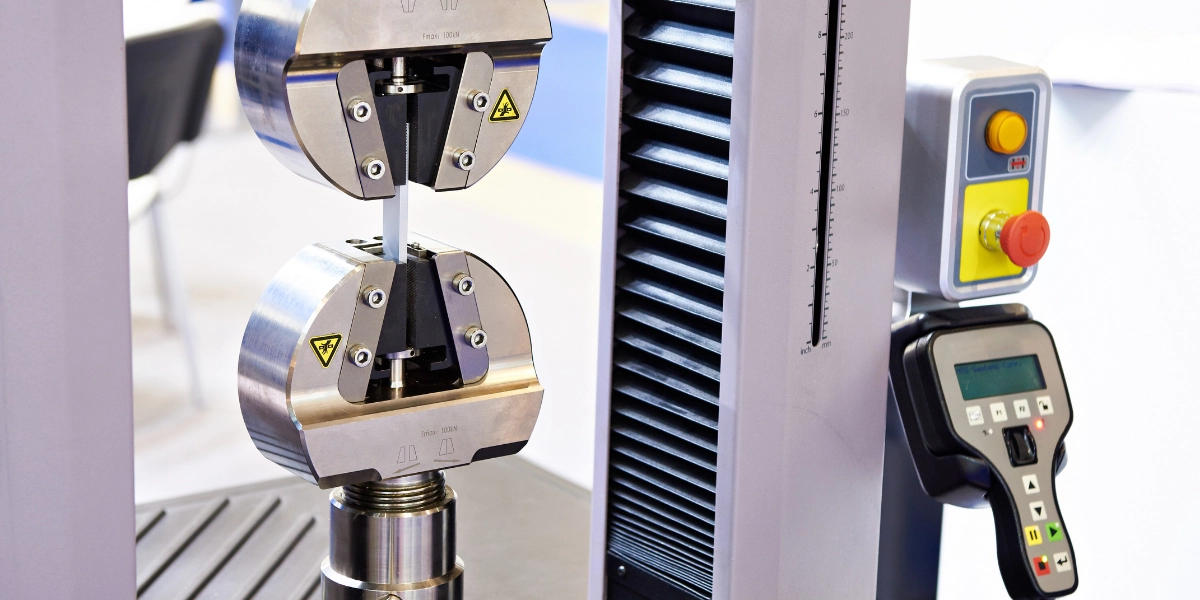

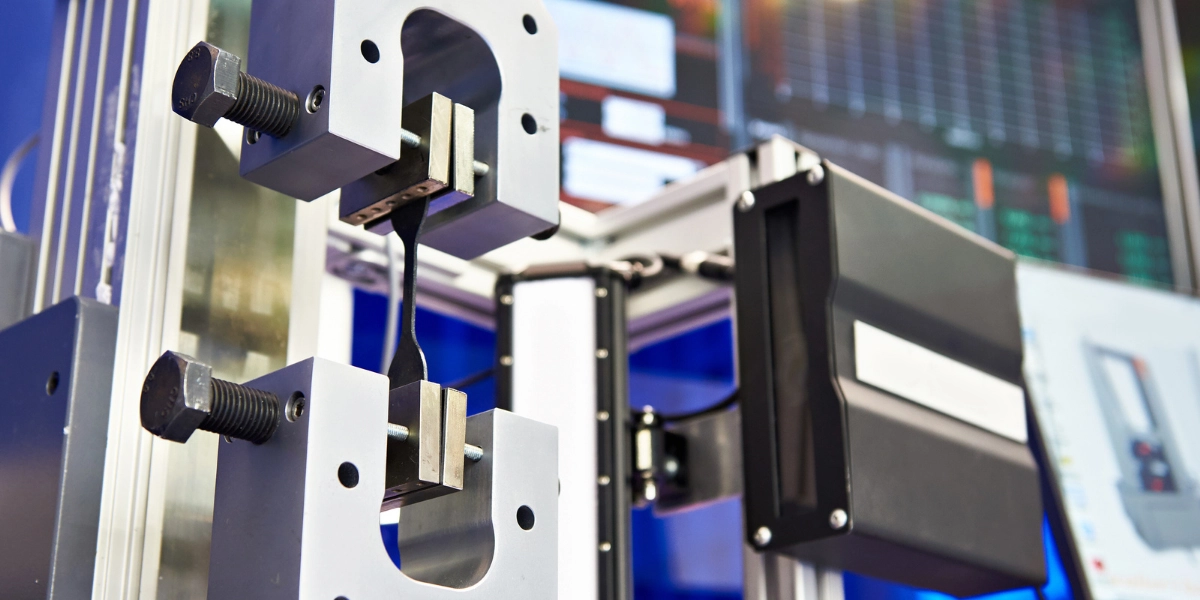

- Tensile testing machine: This is the main device that pulls the sample. It has two clamps—one holds the top of the sample, and the other pulls the bottom.

- Load cell: This sensor measures the force applied to the sample.

- Extensometer or strain gauge: These devices measure how much the sample stretches during the test.

- Specimen grips: They hold the sample firmly in place to prevent slipping.

- Software system: It records data during the test and creates stress-strain curves to show how the material performed.

These tools work together to give accurate results about the material’s strength and flexibility.

Step-by-Step Procedure of a Tensile Test

- Prepare the sample: The material is shaped into a specific size and form—usually a flat strip or a round rod. The shape follows standardized guidelines to ensure consistency.

- Install the sample: The sample is placed in the testing machine, clamped securely at both ends.

- Set the machine: Operators input details like the speed of pulling and the length of the sample into the software.

- Start the test: The machine slowly pulls the sample. The load cell records the force applied, and the extensometer tracks how much the sample stretches.

- Observe the break: The test continues until the sample breaks. This point gives key data on the material’s ultimate strength and elasticity.

- Review the results: After the break, the machine software creates graphs and data showing how the material behaved. These results help users understand the material’s performance.

Tensile testing is widely used in industries like aerospace, automotive, and even dentistry to ensure materials can handle real-world forces.

Mechanical Properties Measured by Tensile Testing

Tensile testing doesn’t just show when a material breaks—it tells us a lot about how the material behaves under stress. This includes how much force it can take, how much it stretches, and how flexible or stiff it is. These properties are important for choosing the right material for different uses, from airplane parts to dental fillings. Let’s explore the key mechanical properties that tensile testing helps us understand.

Yield Strength

Yield strength is the point where the material starts to change shape permanently. Before this point, if the force is removed, the material goes back to its original shape. But after reaching the yield point, the material will no longer return to its starting form—it has been permanently deformed.

For example, in tensile testing, if a dental composite resin shows a high yield strength, it means it can resist biting forces better without cracking or losing its shape. This is especially important when designing products for load-bearing areas in the mouth or for industrial parts that experience constant stress.

Ultimate Tensile Strength (UTS)

Ultimate Tensile Strength (UTS) is the maximum force a material can handle before it starts to neck, which is the point just before it breaks. This value shows how strong the material really is.

Knowing the UTS helps engineers and dentists pick materials that will last longer and perform better in high-stress situations. In composite testing, for instance, UTS values are essential when comparing different resins and fibers to find the most durable combinations.

Modulus of Elasticity (Young’s Modulus)

The modulus of elasticity, also called Young’s modulus, measures stiffness. It tells us how much a material stretches under a certain load. A high modulus means the material is stiff and resists stretching, while a low modulus means it is more flexible.

In dental and industrial applications, stiffness can be good or bad depending on the need. A stiff material might hold its shape well but could be too brittle for areas that need flexibility. That’s why understanding Young’s modulus is key when choosing between different types of resins in composites.

Elongation and Ductility

Elongation measures how much a material can stretch before breaking. Ductility is related—it shows how easily a material can be drawn into a wire or bent without breaking. Materials with high elongation and ductility can absorb more energy before they fail.

This is especially useful for materials that experience repeated stress, such as chewing or bending. In health tourism or dental work, using a material with good elongation means fewer repairs and better patient comfort over time.

Tensile testing gives us a deep look into how materials behave under stress. From measuring strength and flexibility to helping choose the right composite or resin, this method plays a key role in product development and quality control. Whether you’re working with dental materials or advanced industrial parts, understanding these properties ensures better performance, longer-lasting results, and improved safety. As material science continues to evolve, tensile testing remains a reliable way to guide smarter decisions in both everyday and high-tech applications.