- Blog

- 21 Aug 2025

Understanding Hand Lay-Up Composite Manufacturing Process

The hand lay-up composite manufacturing process is one of the oldest and simplest ways to make composite products. It is used in many industries, including automotive, marine, and aerospace, as well as in dental and medical applications. This method is popular because it is low-cost, flexible, and easy to learn. In this article, we will explain what the hand lay-up composite manufacturing process is, how it works step by step, what materials and tools are needed, where it is used, and how you can improve the quality of your results.

What is Hand Lay-Up Composite Manufacturing Process?

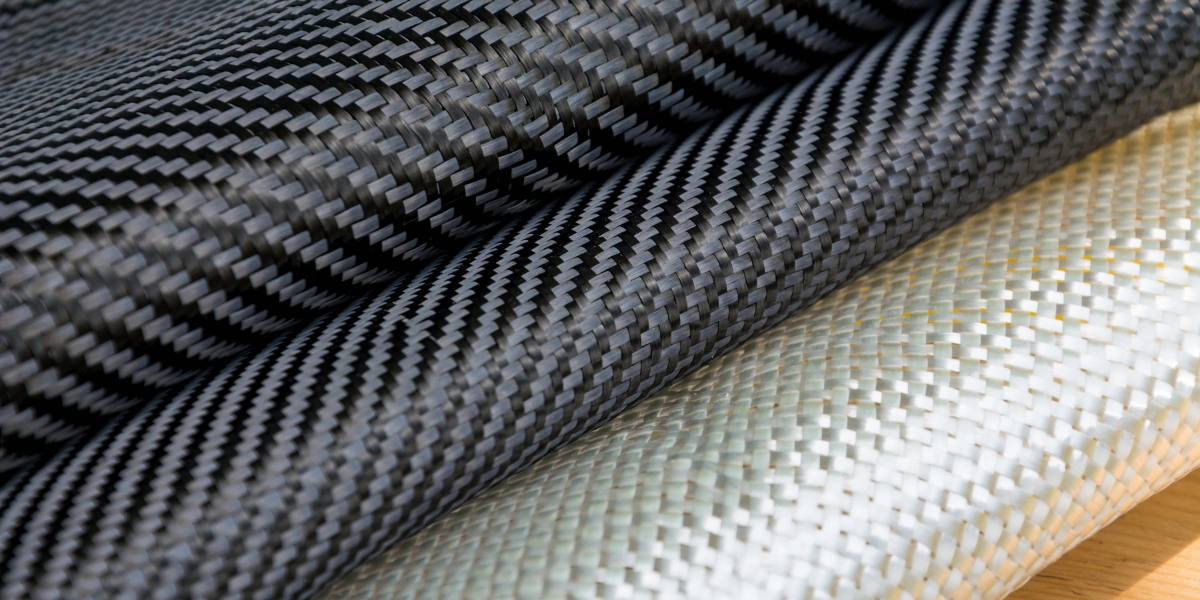

The hand lay-up composite manufacturing process is a simple method used to make strong, lightweight composite parts by hand. In this process, layers of fiber materials (like fiberglass or carbon fiber) are placed by hand into a mold. Then, resin is applied over the fibers to hold them together and make the final product hard and strong.

This method does not require expensive machines, which makes it popular for small production runs or custom-made parts. It is often used when large or complex shapes are needed, like in boat hulls, car parts, or even dental and medical tools. One important part of this process is using mold release agents, which help ensure that the finished part can be easily removed from the mold without damage.

Compared to other composite manufacturing processes, the hand lay-up method is easy to control and flexible. However, it also depends a lot on the skill of the worker, so training and attention to detail are very important.

Hand Lay-Up Composite Manufacturing Process Explained

The hand lay-up composite manufacturing process is a manual method, meaning it is done by hand instead of machines. It works by layering fiber sheets, like fiberglass or carbon fiber, inside a mold. Then, resin is applied over the fibers to wet them out, making sure they stick together and form a hard, solid part after curing (drying).

This process is widely used because it allows for flexibility in shape and design. It is perfect for making small numbers of parts or large parts that would be too costly to make with machines. It’s also a great choice when you want to test a design before moving to bigger production.

Step-by-Step Process

Here is how the hand lay-up process works, step by step:

- Prepare the mold: Clean the mold and apply mold release agents to prevent the part from sticking.

- Cut the fibers: Cut the reinforcement materials (like fiberglass) into the right shapes and sizes.

- Lay the fibers: Place the fiber layers into the mold by hand, arranging them carefully to cover all areas.

- Apply resin: Use a brush or roller to apply resin over the fibers, making sure all fibers are wet. There are different types of resins in composites, such as polyester, vinyl ester, or epoxy, and each has its own benefits.

- Roll out air bubbles: Use a hand roller to remove air bubbles trapped between layers, which can weaken the part.

- Cure the part: Let the part harden at room temperature or with added heat, depending on the resin used.

- Remove and finish: Take the hardened part out of the mold and trim or sand the edges as needed.

Materials and Tools Used

To carry out the hand lay-up composite manufacturing process, you need:

- Fibers: Commonly fiberglass, carbon fiber, or Kevlar.

- Resins: Such as polyester, epoxy, or vinyl ester resins.

- Mold release agents: To make sure the part comes out of the mold easily.

- Molds: Can be made of metal, plastic, or composite materials, shaped to the design you want.

- Hand tools: Brushes, rollers, scissors, gloves, mixing containers, and sometimes heaters for curing.

These materials and tools are usually easy to get and don’t require big investments, making hand lay-up one of the most accessible composite manufacturing processes available.

Applications and Use Cases

The hand lay-up composite manufacturing process is used in many industries because it is simple, flexible, and cost-effective. In the marine industry, it is commonly used to make boat hulls, decks, and other large parts, as the method works well for big shapes and curved surfaces.

In the automotive industry, it helps produce car body parts, spoilers, and dashboards, especially for custom or low-volume vehicles. Aerospace companies use it to create interior panels, fairings, and non-structural components where saving weight is important.

In the construction field, it is used to manufacture panels, tanks, and decorative elements that need to be lightweight but strong. The dental and medical fields also benefit from this process, for example in making dental trays, splints, and custom medical equipment where precision and adaptability matter.

Additionally, the sports equipment industry uses hand lay-up to build items like surfboards, canoes, and protective gear that require strong, lightweight materials. These examples show how versatile the hand lay-up method is, making it perfect for custom, prototype, or large-sized parts where manual control is an advantage.

Tips for Quality Improvement

To improve the quality of products made with the hand lay-up composite manufacturing process, there are several useful tips. First, always prepare the mold carefully by cleaning it and applying the right amount of mold release agents to avoid sticking or surface defects. Next, use high-quality fibers and the correct type of resin for your project, as different types of resins in composites offer different strengths, flexibility, and curing times. It is also important to apply the resin evenly over the fibers and to use rollers to remove air bubbles, as trapped air can weaken the final part. Controlling the working environment helps too — keeping the workspace clean and at a stable temperature can improve curing results. Finally, training and experience matter: workers should be well-trained to place the layers correctly

and work efficiently, as manual errors can reduce the strength and look of the final product.

By following these tips, you can achieve stronger, smoother, and longer-lasting composite parts.