- Blog

- 17 Oct 2025

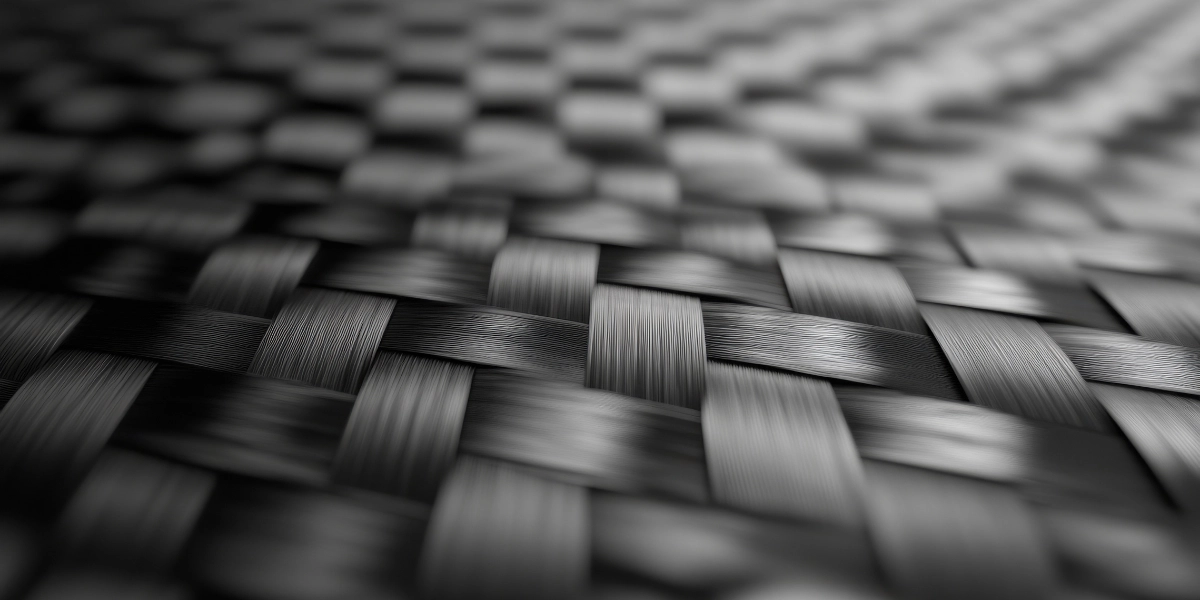

How to Calculate Fiber Volume Fraction in Composites

In composite materials, understanding the fiber volume fraction is essential for predicting performance and quality. This value tells us how much of the composite is made up of fibers compared to the resin. Knowing it helps manufacturers improve strength, reduce weight, and optimize production. Whether you’re working in aerospace, automotive, or construction, calculating this value correctly can make a big difference in results.

What Is Fiber Volume Fraction?

Fiber volume fraction is the ratio of the volume of fibers to the total volume of a composite material. It shows how much of the material is made up of reinforcing fibers compared to the resin matrix. This value is usually expressed as a decimal or a percentage. For instance, if a composite contains 60% fiber and 40% resin by volume, the fiber volume fraction is 0.60.

This ratio plays a key role in the mechanical performance of composites. A higher fiber volume fraction often leads to increased strength and stiffness, while also reducing weight. However, the quality of the final product also depends on other factors like fiber alignment, resin distribution, and void content.

The ideal fiber volume fraction varies depending on the application, the fiber type, and the types of resins in composites. It’s also influenced by the chosen method during the processing of composite materials, such as hand lay-up, resin transfer molding, or pultrusion.

Understanding this value helps engineers design better products and allows manufacturers to maintain quality and consistency. It’s one of the most important parameters when working with composite materials.

Key Concepts Before You Calculate

Before calculating the fiber volume fraction, it’s important to understand a few basic concepts. These ideas help you choose the right method and avoid mistakes during measurement.

First, you need to know the composite density. This is the total density of the material, which includes both the fiber and the resin. It is often measured in grams per cubic centimeter (g/cm³). You also need the individual densities of the fiber and the resin. These values are used in most calculation formulas.

Next, it’s important to know the fiber and resin weight or volume used in the composite. This data is often collected during the manufacturing process. Make sure the values are accurate and measured under the same conditions.

Also, remember that moisture, air bubbles, or uneven fiber placement can affect your results. These small issues may lead to big errors in the final value.

Finally, the fiber layout and type—such as unidirectional or woven—can influence the results. So it’s best to keep the manufacturing method and material type consistent when comparing different samples.

By understanding these concepts, you’ll be better prepared to measure the fiber volume fraction correctly and get reliable data for product quality and performance.

Methods to Calculate Fiber Volume Fraction in Composites

There are several ways to calculate the fiber volume fraction of a composite material. The best method depends on the type of composite, available tools, and how precise the results need to be. In most industrial and laboratory settings, the most common approach uses density and weight measurements. This method is popular because it is simple, fast, and gives reliable results when the material data is accurate.

Let’s look at how this method works and the formula used in the calculation.

Calculation Using Density and Weight Measurements

To begin, you need to know three main values:

- The total weight of the composite sample

- The weight or volume of the fiber

- The composite density, and the individual densities of both fiber and resin

These values can be measured directly or obtained from technical data sheets. Once you have this information, you can calculate how much of the composite’s volume is made up of fibers.

This method is especially useful when working with cured laminates or final products, where cutting and testing small samples is possible. For example, in quality control labs, small pieces are taken from larger parts and measured to check if they meet the design targets.

Be sure to use accurate scales and always remove any moisture or dust from the sample, as this can affect the result.

Formula for Fiber Volume Fraction (Vf)

The most common formula used is:

- Vf = (Wf / ρf) / [(Wf / ρf) + (Wr / ρr)]

Where:

- Vf = Fiber volume fraction

- Wf = Weight of the fiber

- ρf = Density of the fiber

- Wr = Weight of the resin

- ρr = Density of the resin

This formula calculates how much space the fibers take up in the total volume. The result is usually a decimal (e.g., 0.55), which can be converted to a percentage (e.g., 55%).

When used correctly, this method gives a good estimate of the fiber content in a composite part. It’s also one of the most cost-effective techniques in everyday applications.

Experimental Techniques for Measuring Fiber Volume Fraction

While calculation methods are useful, sometimes direct measurement is needed for more accurate or research-level results. There are several experimental techniques used to measure the fiber volume fraction in composite materials. These methods are often used in labs or during material development stages.

Burn-Off Test (Matrix Digestion)

One of the most common experimental methods is the burn-off test, also known as matrix digestion. In this method, a sample of the composite is heated in a furnace to remove the resin, leaving only the fibers behind. By weighing the sample before and after the burn-off, it is possible to calculate the amount of fiber and then determine the volume fraction.

This method works well for thermoset composites and is widely used because it gives direct results. However, it requires special equipment and can damage the fibers if the temperature is not controlled properly.

Microscopy Image Analysis

Another technique uses cross-sectional images of the composite taken with a microscope. The fiber areas are measured using image analysis software. This method is especially useful for detecting uneven fiber distribution or voids. It is very accurate but takes more time and requires trained personnel.

Ultrasonic and X-ray Techniques

Advanced methods like ultrasonic testing and X-ray scanning can also be used. These non-destructive tests measure the internal structure of the composite and estimate fiber volume based on density changes. They are more expensive but useful when the sample cannot be damaged.

These experimental techniques are often used together with calculation methods to confirm the results. They help engineers better understand material behavior and improve processing of composite materials by providing deeper insight into fiber distribution and quality.

Common Errors and How to Avoid Them

When calculating or measuring fiber volume fraction, even small mistakes can lead to incorrect results. These errors can affect product quality, strength, and performance. Below are some common mistakes and tips on how to avoid them.

1. Using Incorrect Density Values

Many people use estimated or outdated values for fiber and resin densities. This can lead to big errors in the final calculation. Always use the correct and up-to-date values from material data sheets or test results. Even small changes in composite density can impact the accuracy.

2. Not Removing Moisture or Contaminants

If the composite sample contains moisture, dust, or other particles, the weight will be higher than it should be. This gives a false reading. Before testing, make sure the sample is clean and dry.

3. Poor Sample Preparation

In experimental methods, improper cutting or handling of the sample can cause damage or deformation. This affects the results, especially in microscopy or burn-off tests. Use sharp tools and follow standard procedures for sample preparation.

4. Ignoring Resin Loss During Processing

During the production of a composite, some resin may be lost due to leakage, evaporation, or overflow. If this is not considered in the calculation, it may seem like the fiber volume is higher than it really is. Understanding the behavior of the types of resins in composites can help reduce this problem.

5. Overreliance on One Method

Using only one method—calculation or experiment—may not always give the full picture. If possible, compare results from different techniques. This helps confirm accuracy and gives more confidence in the data.

By avoiding these common errors, companies can improve the reliability of their measurements, reduce waste, and ensure better performance from their products.

Understanding how to calculate and measure fiber volume fraction is essential for producing strong, lightweight, and reliable composite materials. Whether you’re using simple weight and density methods or advanced experimental techniques, accuracy is key. By learning the core concepts, using the right formulas, and avoiding common mistakes, engineers and manufacturers can improve product quality and reduce costs. A well-controlled fiber volume fraction not only boosts performance but also supports more efficient and consistent processing of composite materials.