- Blog

- 7 Mar 2025

How Carbon Fiber Recycling is Transforming Sustainability

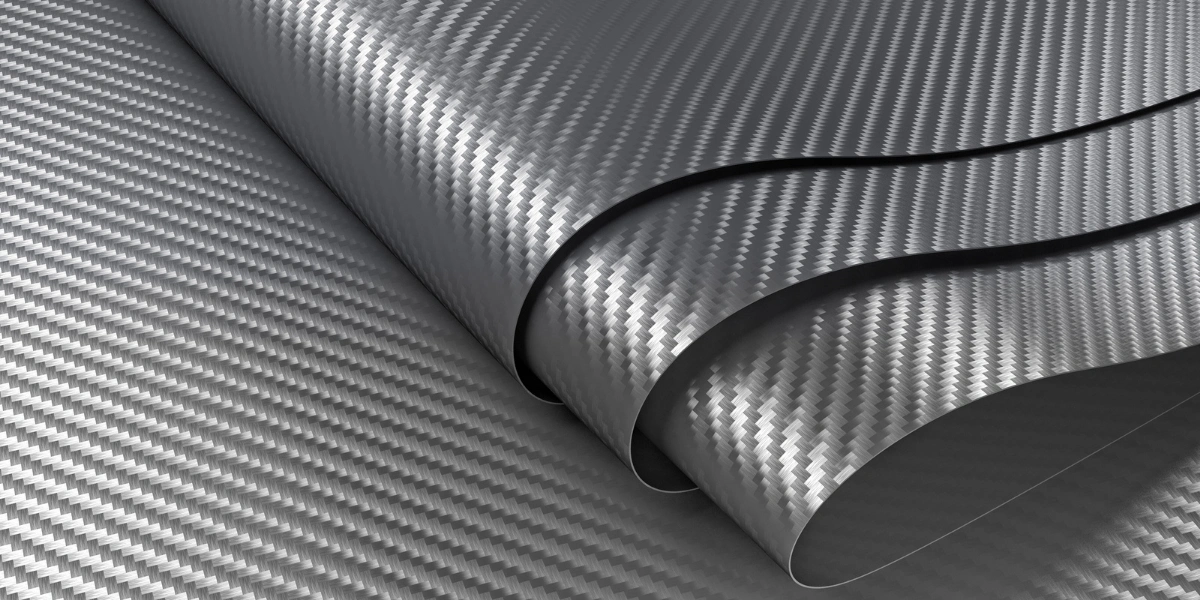

Carbon fiber has become a critical material in industries like aerospace, automotive, and construction due to its exceptional strength, lightweight nature, and durability. However, the rising demand for carbon fiber also brings challenges, particularly related to waste generation and environmental sustainability. Carbon fiber recycling is emerging as a key solution to reduce waste, conserve resources, and minimize the environmental impact of composite materials.

This article explores carbon fiber recycling, including its definition, methods, benefits, and challenges. By understanding how recycling works, industries can adopt more eco-friendly practices while maintaining material performance.

What is Carbon Fiber Recycling?

Carbon fiber recycling refers to the process of recovering carbon fibers from composite materials, such as outdated products or manufacturing scraps, and preparing them for reuse in new applications. This process helps reduce the demand for virgin carbon fiber, which is both resource-intensive and costly to produce.

Carbon fiber is commonly used in composite materials, where fibers are embedded in a polymer resin. Recycling involves separating these fibers from the resin while preserving their strength and quality for future use. Recovered carbon fibers can be repurposed in industries such as automotive components, sports equipment, aerospace, and even carbon fiber supplements, which are used to reinforce plastic products for added strength and durability.

Methods of Carbon Fiber Recycling

Several methods have been developed to recycle carbon fiber effectively. The choice of method often depends on the desired fiber quality, cost considerations, and environmental impact.

Mechanical Recycling

Mechanical recycling involves shredding or grinding composite waste into smaller pieces. Once the material is broken down, the carbon fibers are separated and collected.

This method is straightforward and cost-effective, making it suitable for large-scale recycling of low-value products. However, mechanical recycling often results in shorter, more damaged fibers, limiting their use to non-structural applications where high strength is not required. Despite its limitations, mechanical recycling remains a popular choice for lower-performance sectors due to its simplicity.

Pyrolysis Recycling

Pyrolysis recycling uses heat to break down the composite material. The composite waste is heated in a controlled, oxygen-free environment, which causes the resin to decompose and leave behind clean carbon fibers.

This method is effective for recovering high-quality fibers suitable for more demanding applications. Pyrolysis preserves fiber strength better than mechanical recycling, making it ideal for industries like aerospace and composite manufacturing processes, where material performance is critical.

However, the process requires significant energy, which can offset some of its sustainability benefits if not managed properly.

Chemical Recycling

Chemical recycling involves the use of solvents and chemical reactions to break down the resin matrix, separating it from the carbon fibers. This process allows for minimal fiber degradation, resulting in high-quality recovered fibers.

Though chemical recycling produces excellent fiber quality, it comes with high costs and potential environmental concerns related to the chemicals used. As a result, it is primarily used for high-end applications where fiber quality is critical, such as aerospace components and advanced composite structures.

Benefits of Recycling Carbon Fiber

Carbon fiber recycling offers numerous benefits that contribute to a more sustainable and cost-effective approach to composite manufacturing.

1. Waste Reduction

Recycling reduces the volume of composite waste sent to landfills, where it can take decades to decompose. This helps minimize pollution and the environmental footprint of carbon fiber products.

2. Energy Conservation

Producing virgin carbon fiber requires substantial energy input due to the complex manufacturing process. Recycling reduces the need for energy-intensive raw material production, contributing to overall energy savings.

3. Cost Efficiency

By recovering valuable fibers, recycling lowers material costs, especially in industries like automotive and sports equipment manufacturing. Recycled fibers are more affordable than virgin fibers, making composite technology accessible for a wider range of applications.

4. Resource Conservation

Recycling carbon fiber reduces the need for virgin material production, which relies on raw materials like polyacrylonitrile (PAN). By preserving existing fibers, industries can conserve these finite resources.

5. Sustainability Across Industries

Recycled carbon fiber can be reused in applications that prioritize eco-friendliness, such as sustainability in construction. Green building projects often seek recycled composites for structural reinforcements, contributing to a circular economy and reduced carbon emissions.

Challenges and Limitations of Carbon Fiber Recycling

While carbon fiber recycling provides significant benefits, several challenges must be addressed to maximize its potential.

1. Fiber Quality Degradation

Some recycling methods, such as mechanical recycling, can damage the fibers, leading to reduced strength and shorter fiber lengths. This limits the use of recycled fibers in high-performance industries.

2. High Processing Costs

Advanced methods like chemical recycling are effective but costly due to specialized equipment and chemical use. These high costs can deter smaller companies from adopting recycling practices.

3. Limited Recycling Infrastructure

The global infrastructure for carbon fiber recycling is still developing. Many regions lack specialized facilities capable of handling composite waste on a large scale, creating logistical challenges.

4. Complex Composite Structures

Many carbon fiber products are part of multi-layered composites that combine different materials. Separating carbon fibers from mixed-material composites can be complex and time-consuming, requiring specialized techniques.

The Future of Carbon Fiber Recycling

Despite the challenges, the future of carbon fiber recycling looks promising. Advancements in chemical and pyrolysis techniques are making the process more efficient and cost-effective. Companies are increasingly investing in sustainable solutions to meet global environmental standards, encouraging broader adoption of recycled materials.

Collaboration between industries, governments, and research institutions can further accelerate progress, making carbon fiber recycling more accessible and scalable. Additionally, innovations in composite manufacturing processes are enabling better integration of recycled fibers into high-performance applications.

In the end, carbon fiber recycling plays a crucial role in promoting sustainability across multiple industries, from aerospace and automotive to sustainability in construction. By reducing waste, conserving resources, and lowering costs, it supports global efforts to create a circular economy.

While challenges remain, ongoing advancements in recycling technologies and infrastructure continue to drive progress. As industries prioritize eco-friendly practices, the role of carbon fiber recycling will only grow, helping build a cleaner, more sustainable future.